Built on Our LAP-C Platform

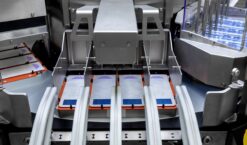

Our blister packaging and sealing machine have been designed with the specific requirements and preferences of our client in mind. We’ve utilized our versatile LAP-C platform as the foundation and customized it to meet all the requirements. With six stations and a highly precise turntable that moves the molds, this system can simultaneously fill and process four blister packages.

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Operation of the Stations

Station 1: Blister denesting Automation

In this station, blisters are automatically placed from a magazine into the four-fold mold, streamlining and enhancing the efficiency of the process.

Station 2: Automatic syringe placement

Here, syringes are manually placed in a chute and are then automatically inserted into the blister. If desired, this station can be fully automated using hoppers, making it ideal for larger quantities or creating a buffer in the supply process.

Station 3: Needles and Syringes

Safely packaged needles are separated and oriented correctly using a vibratory filler. Subsequently, the needles are placed in the blisters in pairs and pressed with the appropriate force.

Station 4: Vision System

This station verifies the presence of all products, including the syringe components, and places a Tyvek lid while ensuring it is correctly positioned.

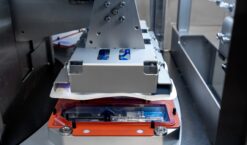

Station 5: Sealing

The blister is accurately sealed within the designated seal window, ensuring product safety.

Station 6: Quality Control

If a product does not pass visual inspection or falls outside the seal window, it is rejected at this station. Approved products are ejected from the machine.

Siemens Control and Compact Design

Our blister packaging and sealing machine utilizes advanced Siemens controls, ensuring reliable and precise operation. Additionally, the LAP-C platform features a compact design, making it suitable for various processes and occupying a small footprint. Convenient docking stations enable the process to operate autonomously for extended periods.

High Efficiency with Just One Operator

For our client, this machine replaced three existing manual sealers, resulting in a quick return on investment. With only one operator overseeing the process, the machine can work efficiently, saving valuable time and resources.

Are you interested in this machine? Contact us for more information and discover how the blister packaging and sealing machine can optimize your business processes.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)