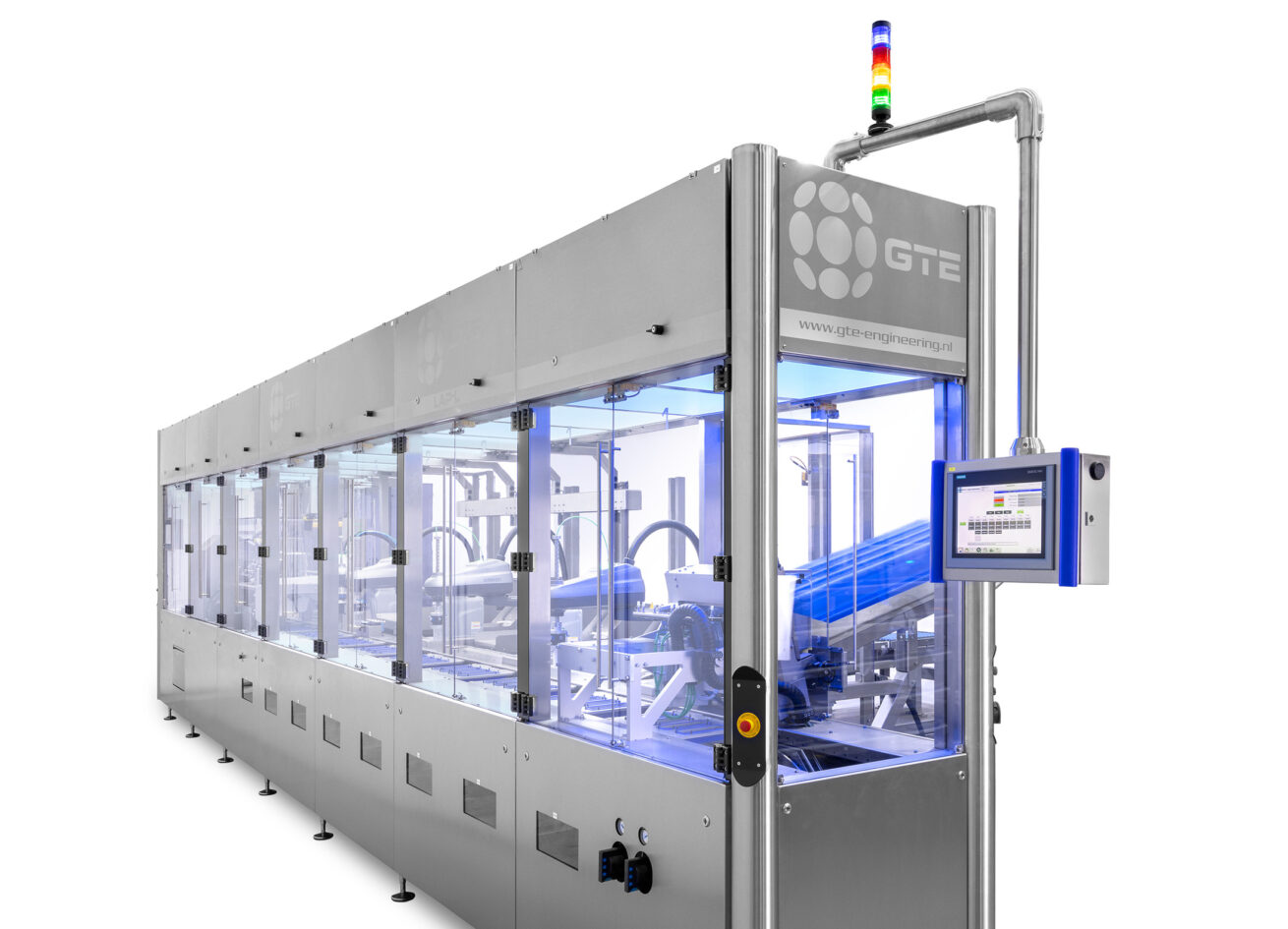

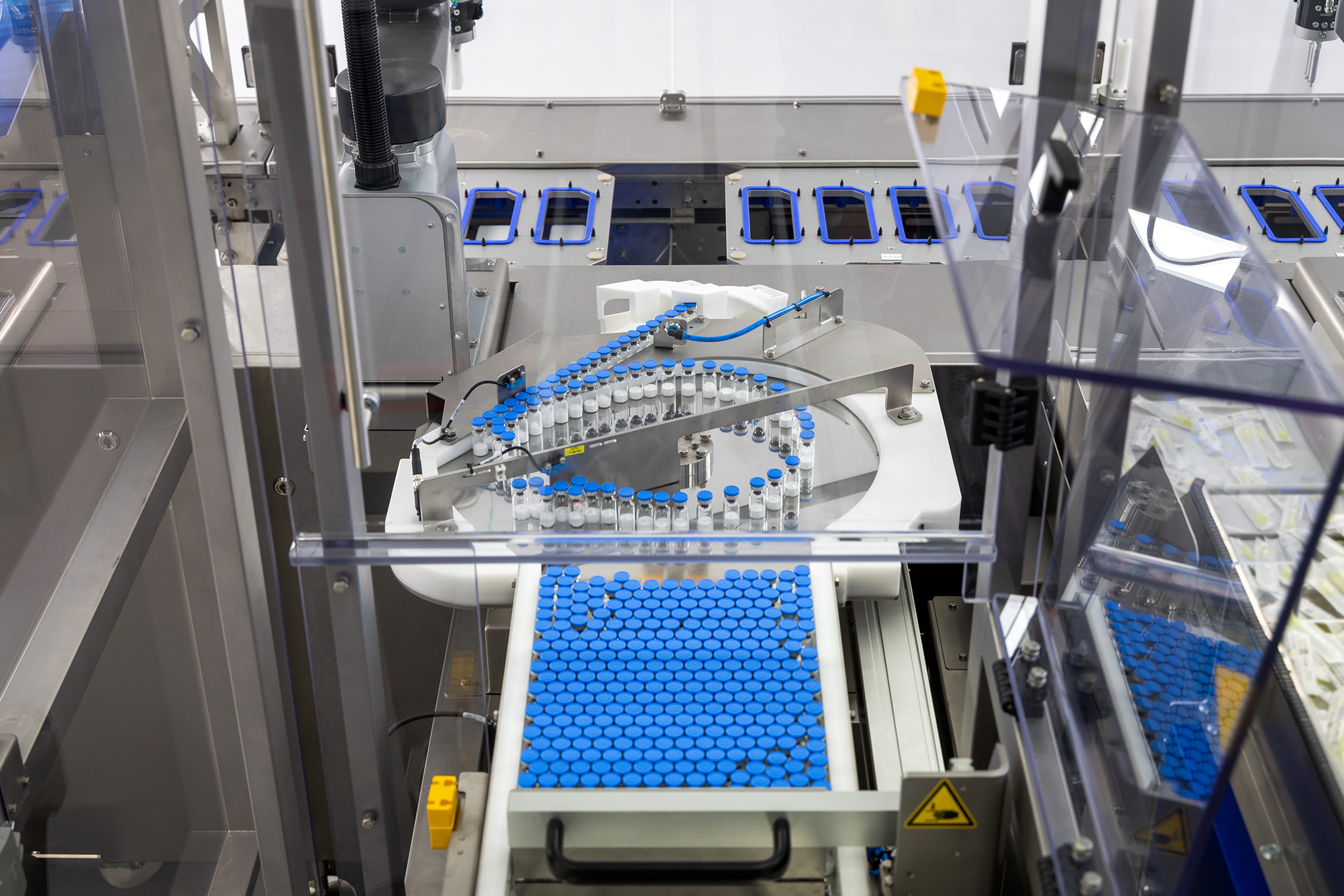

A linear and modular system

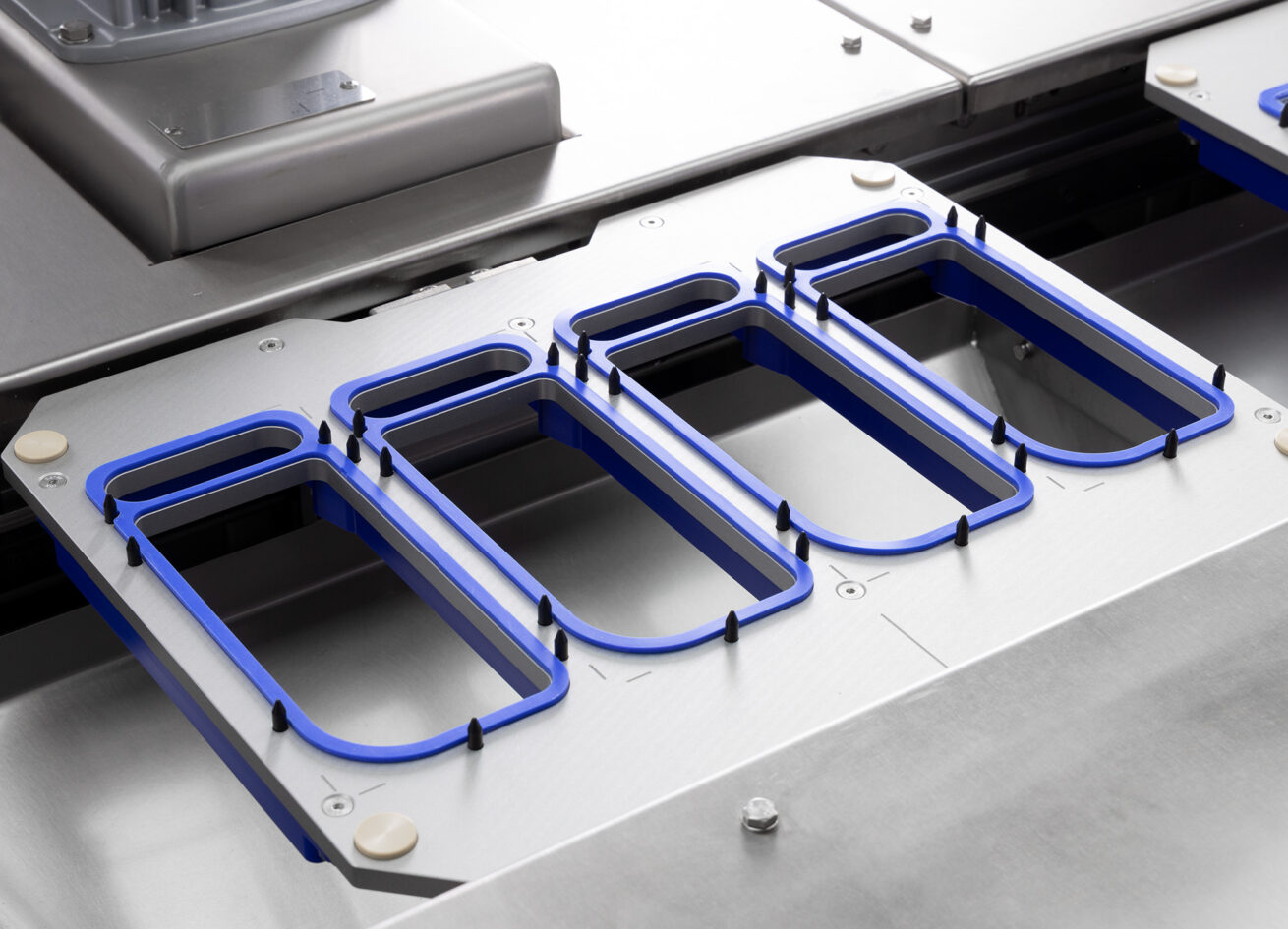

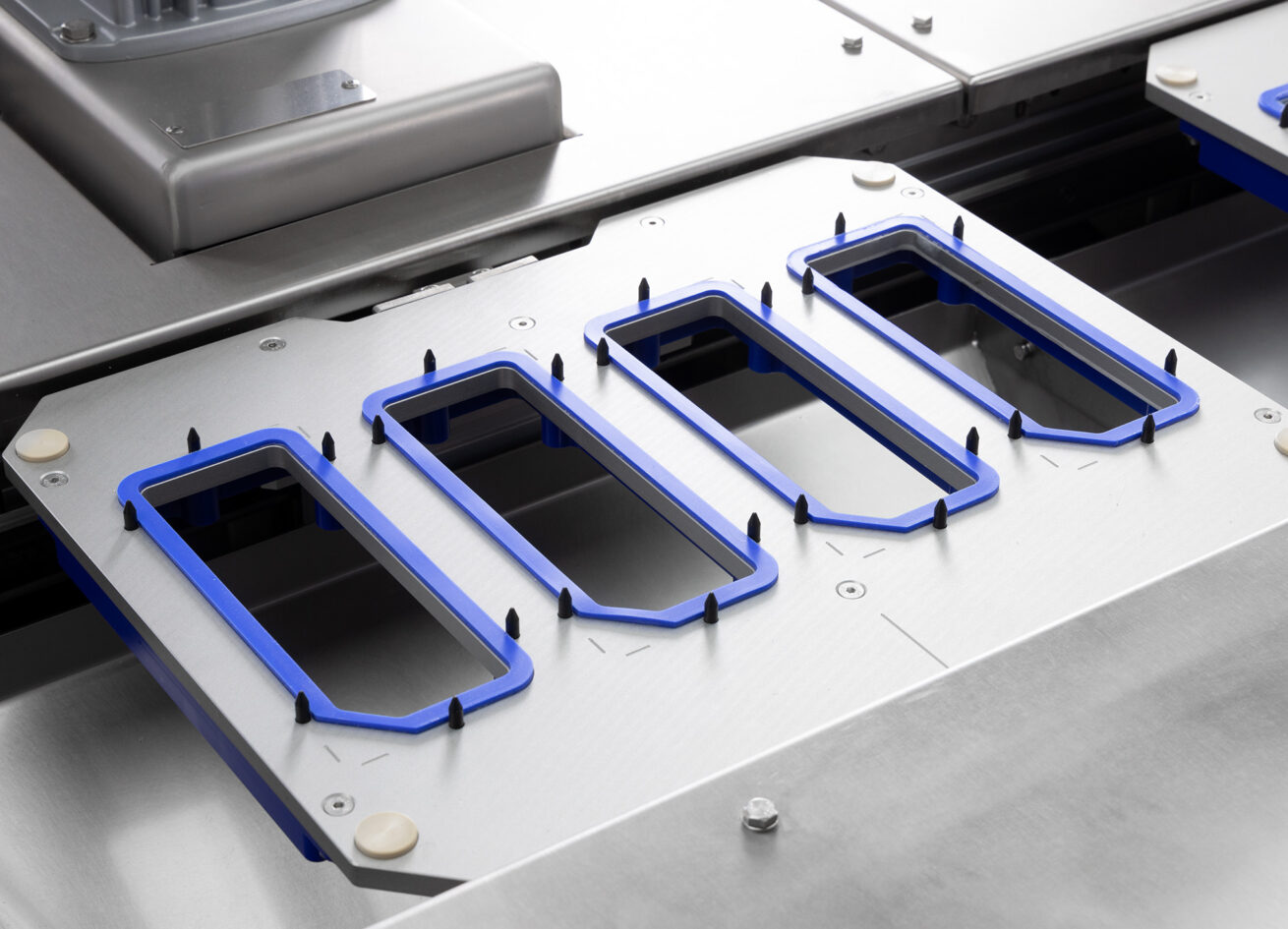

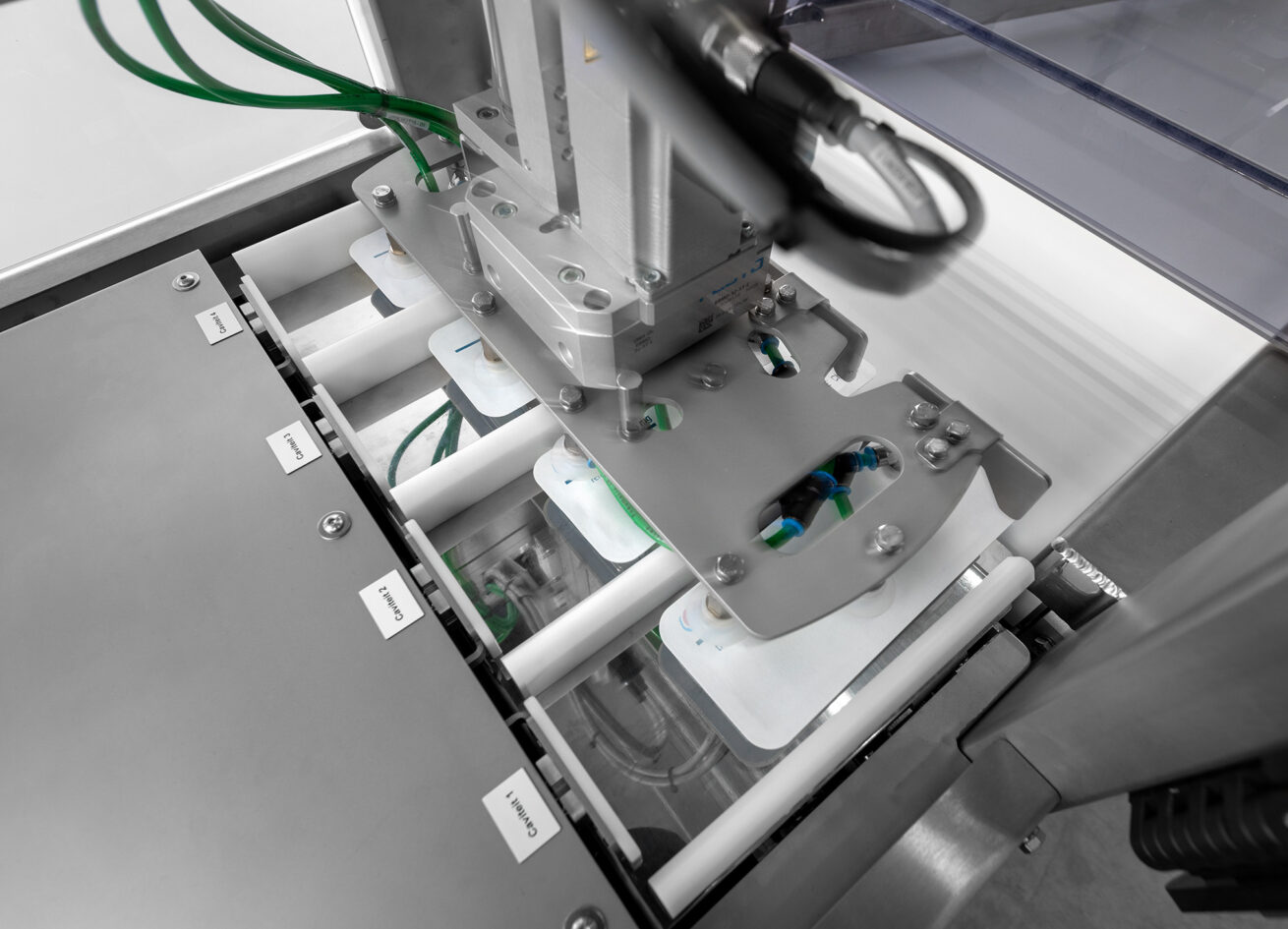

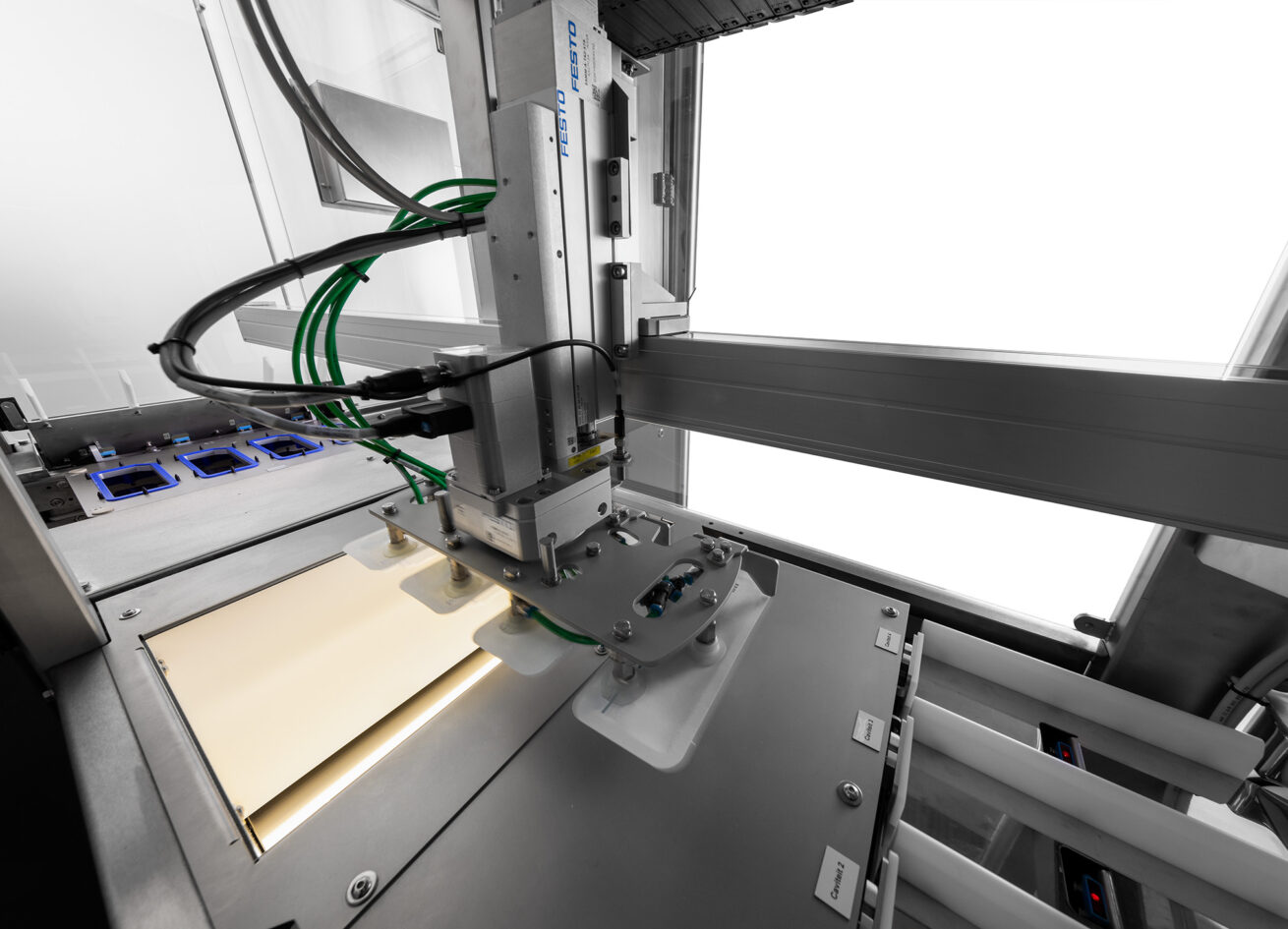

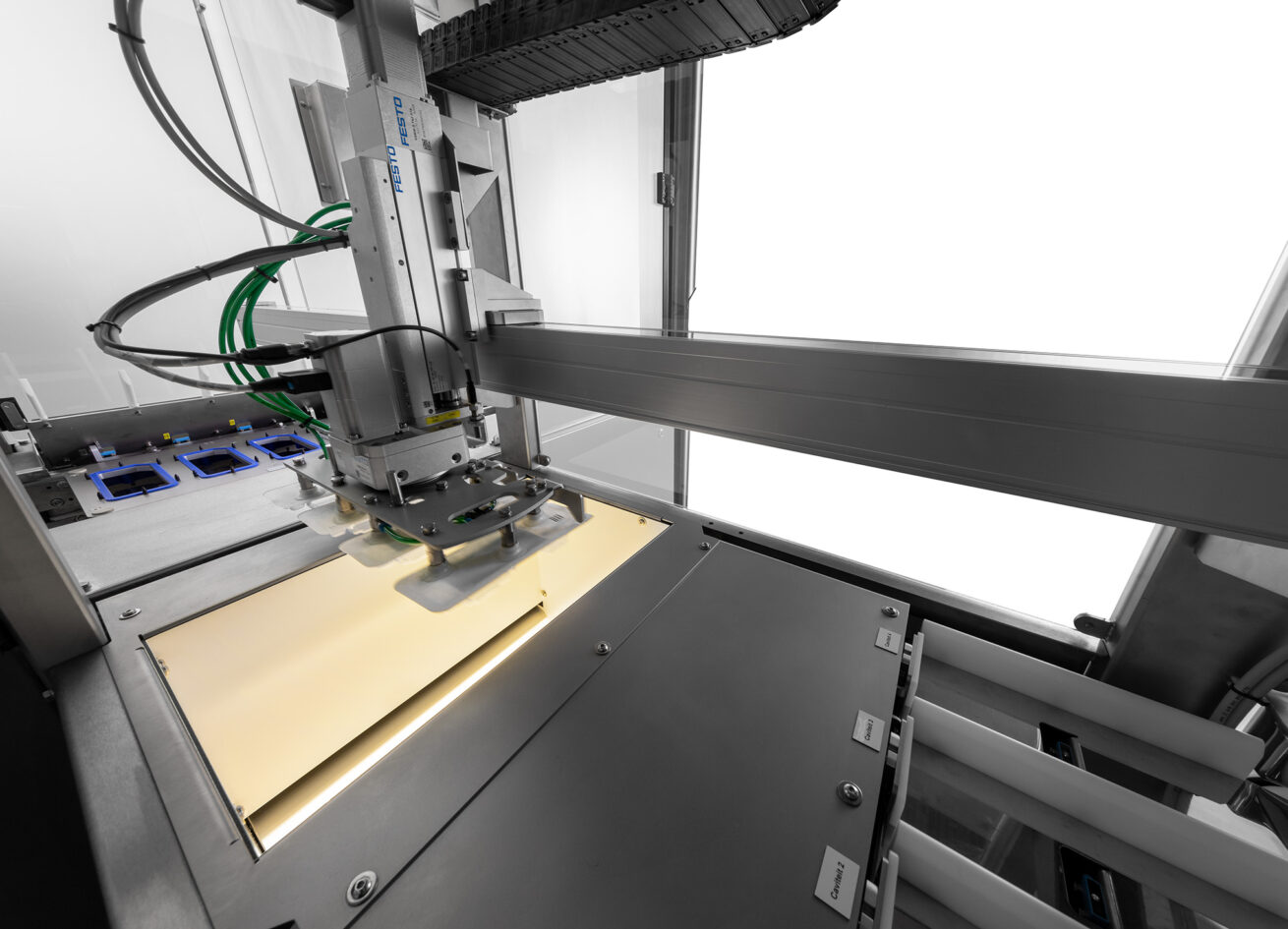

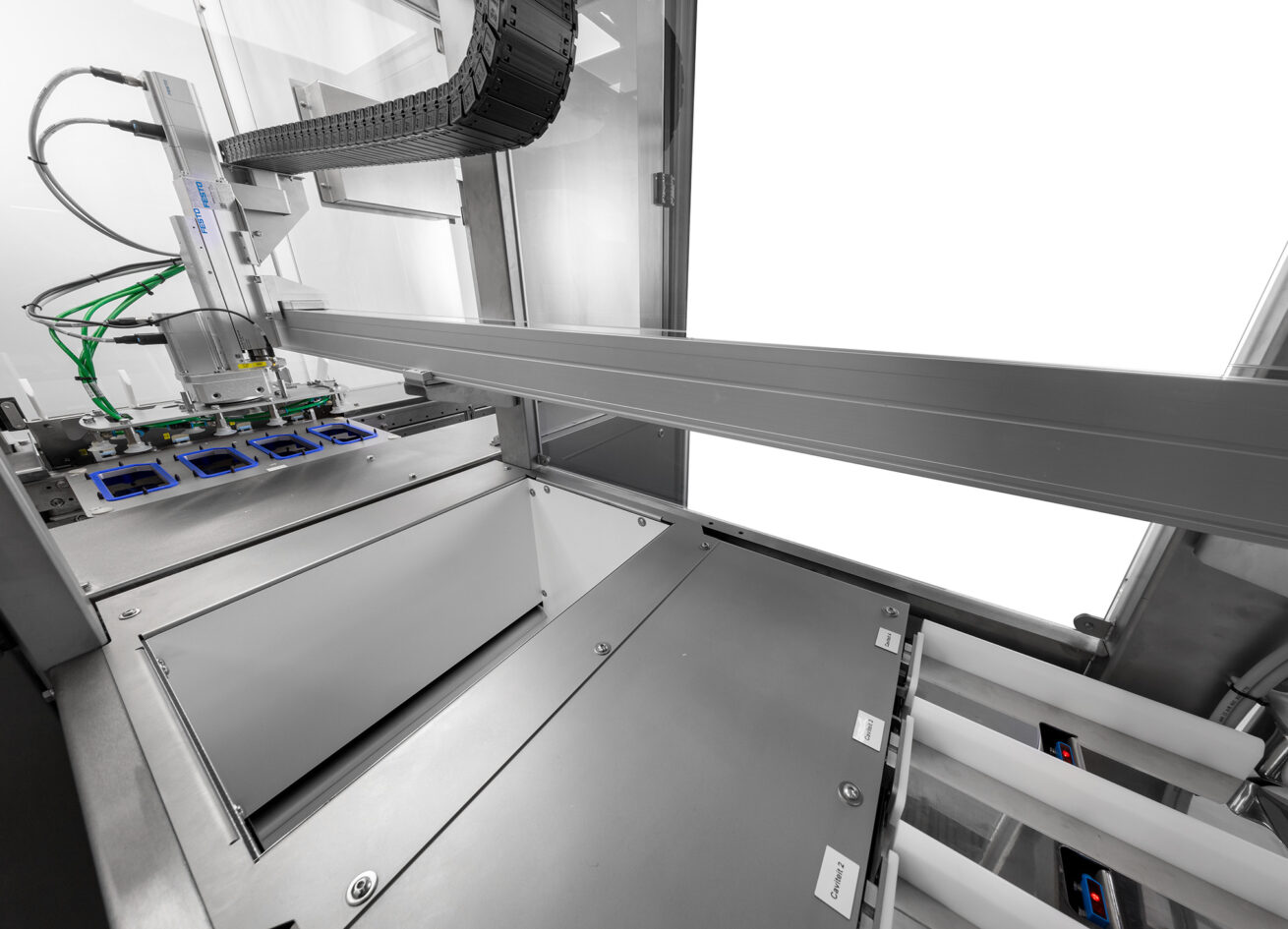

Our client, operating in the medical sector, needed a packaging solution that would allow them to automatically fill and seal two different blisters with various configurations. It was also essential that the machine could be quickly reconfigured for different setups. With this challenge in mind, we developed the LAP-L Platform, a linear and modular system that fulfills all these requirements.

The LAP-L Platform provides the perfect foundation for the LAP-L Blister filling and sealing machine. By customizing our standard platform to our client’s needs, we created a flexible machine that seamlessly fits within the constraints of their cleanroom. With this platform, they have the ability to easily switch between various configurations, making their production processes more efficient.

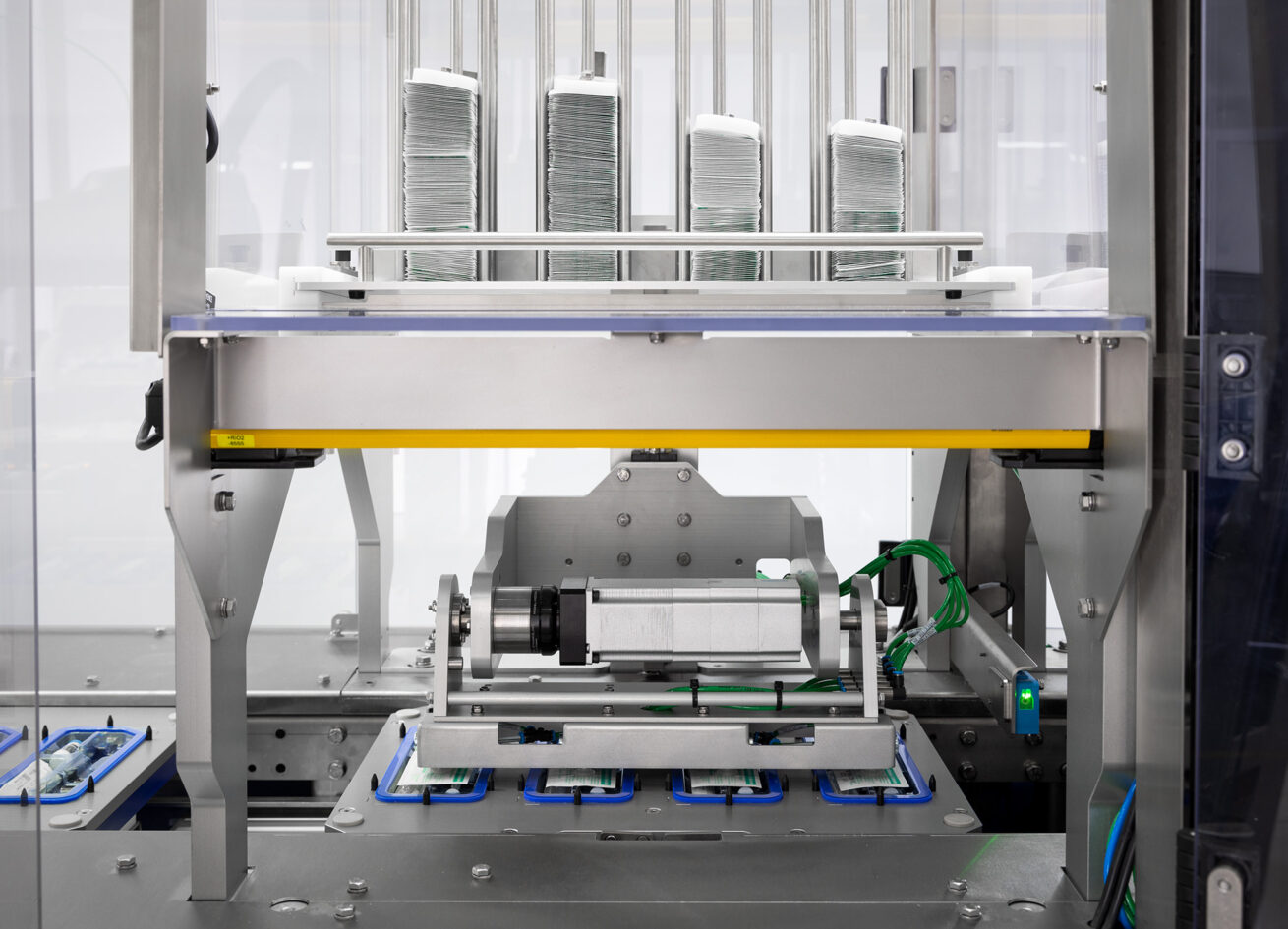

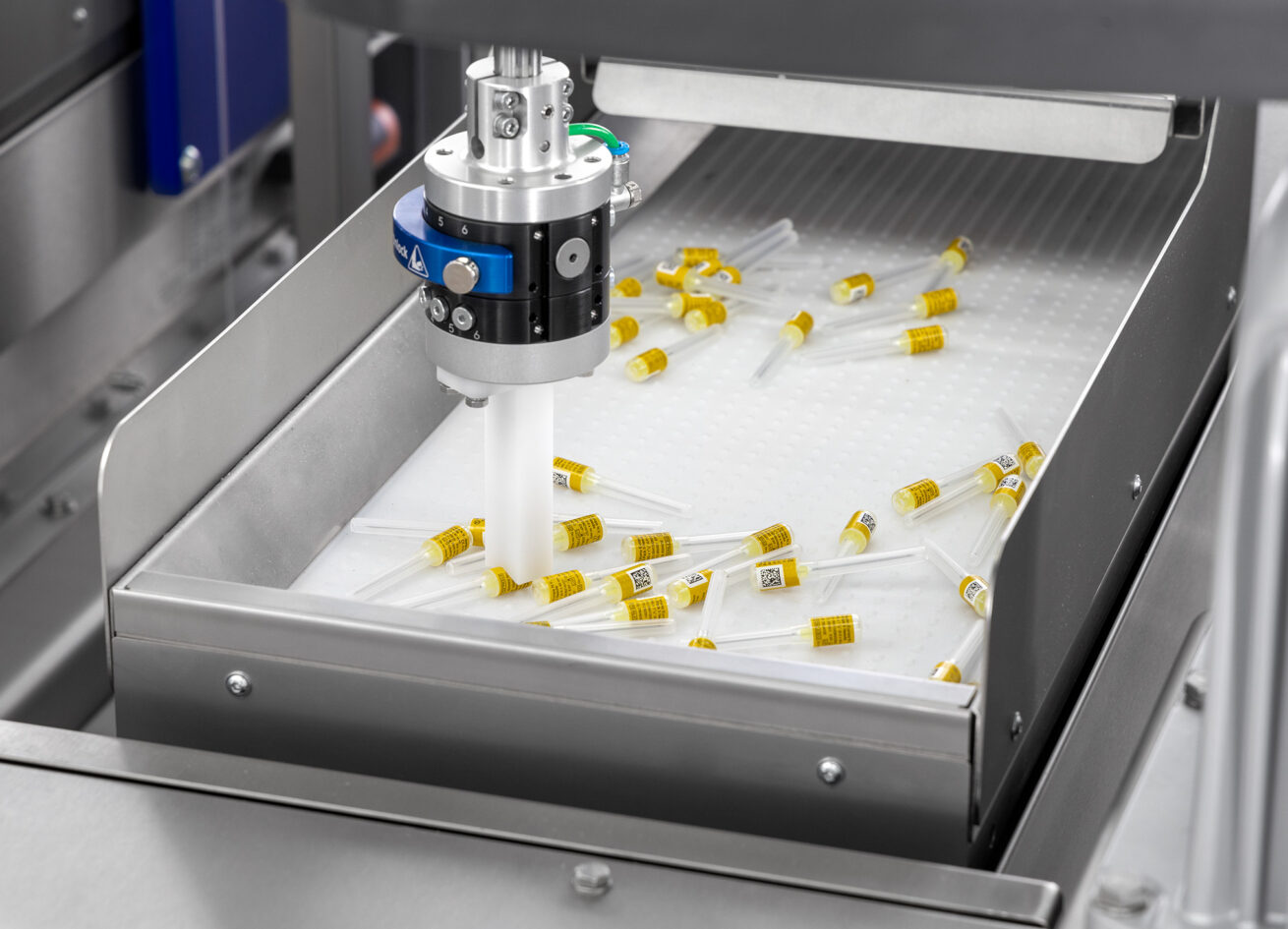

Vision Checks for Optimal Quality

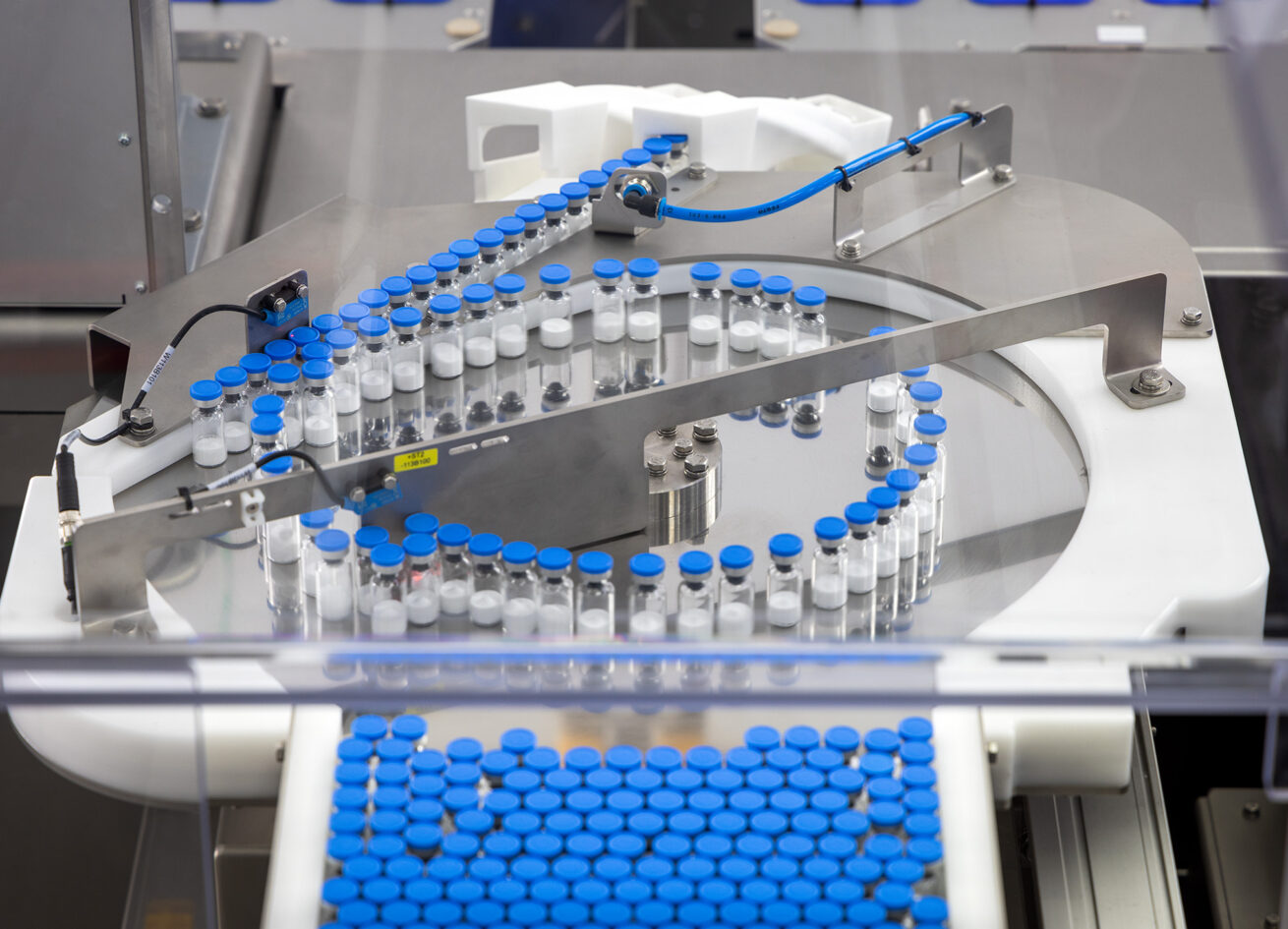

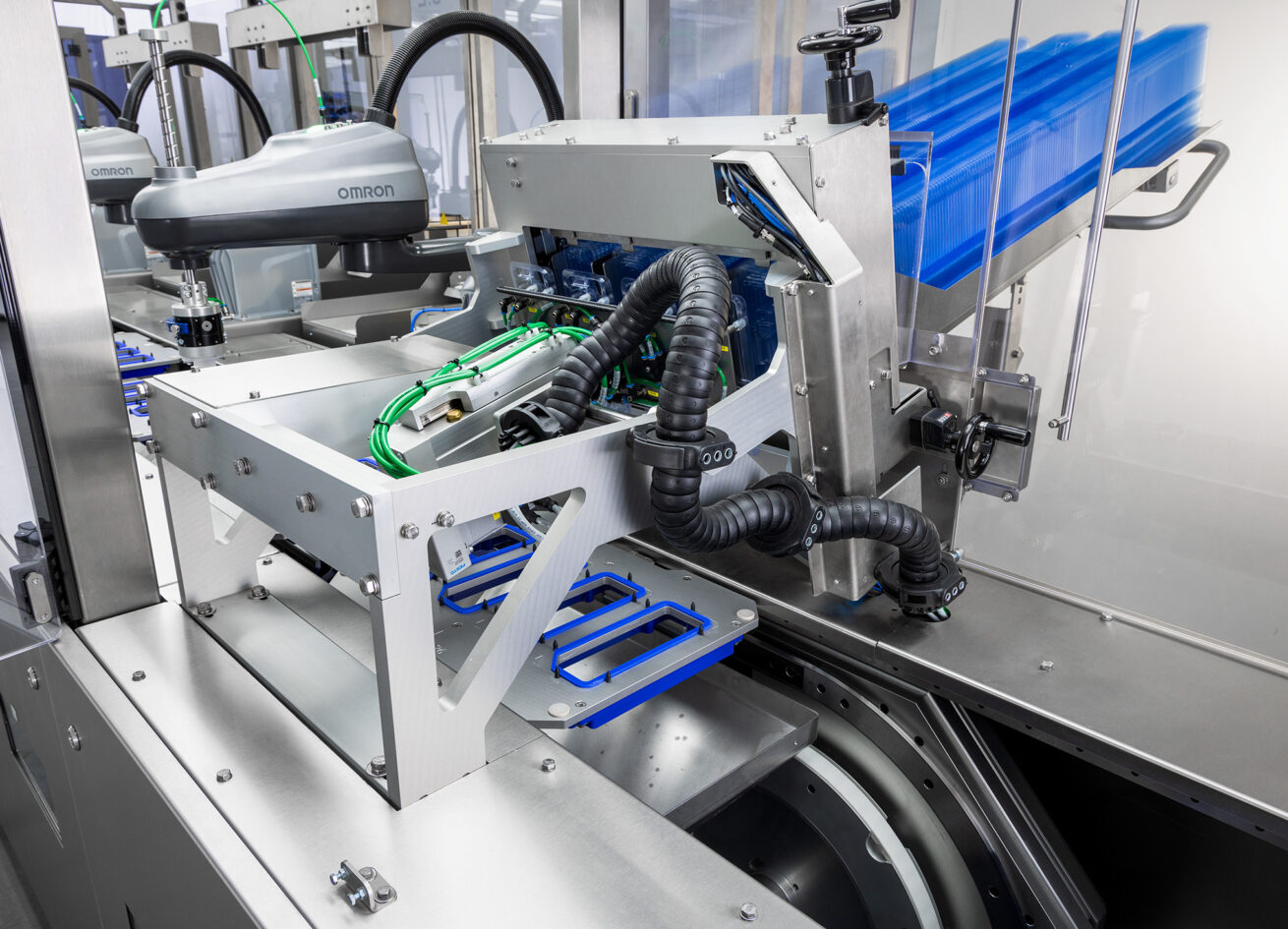

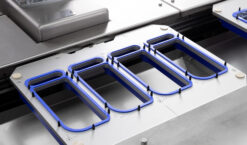

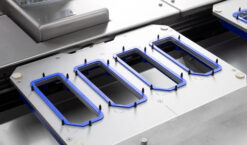

To meet stricter quality standards, we integrated various Vision Checks into the LAP-L blister filling and sealing machine. These Vision Checks ensure our client receives high-quality products. Advanced cameras ensure proper orientation of all bulk products and verify the correct positioning of each product. Subsequently, a SCARA robot is deployed to precisely place the products in the blister.

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

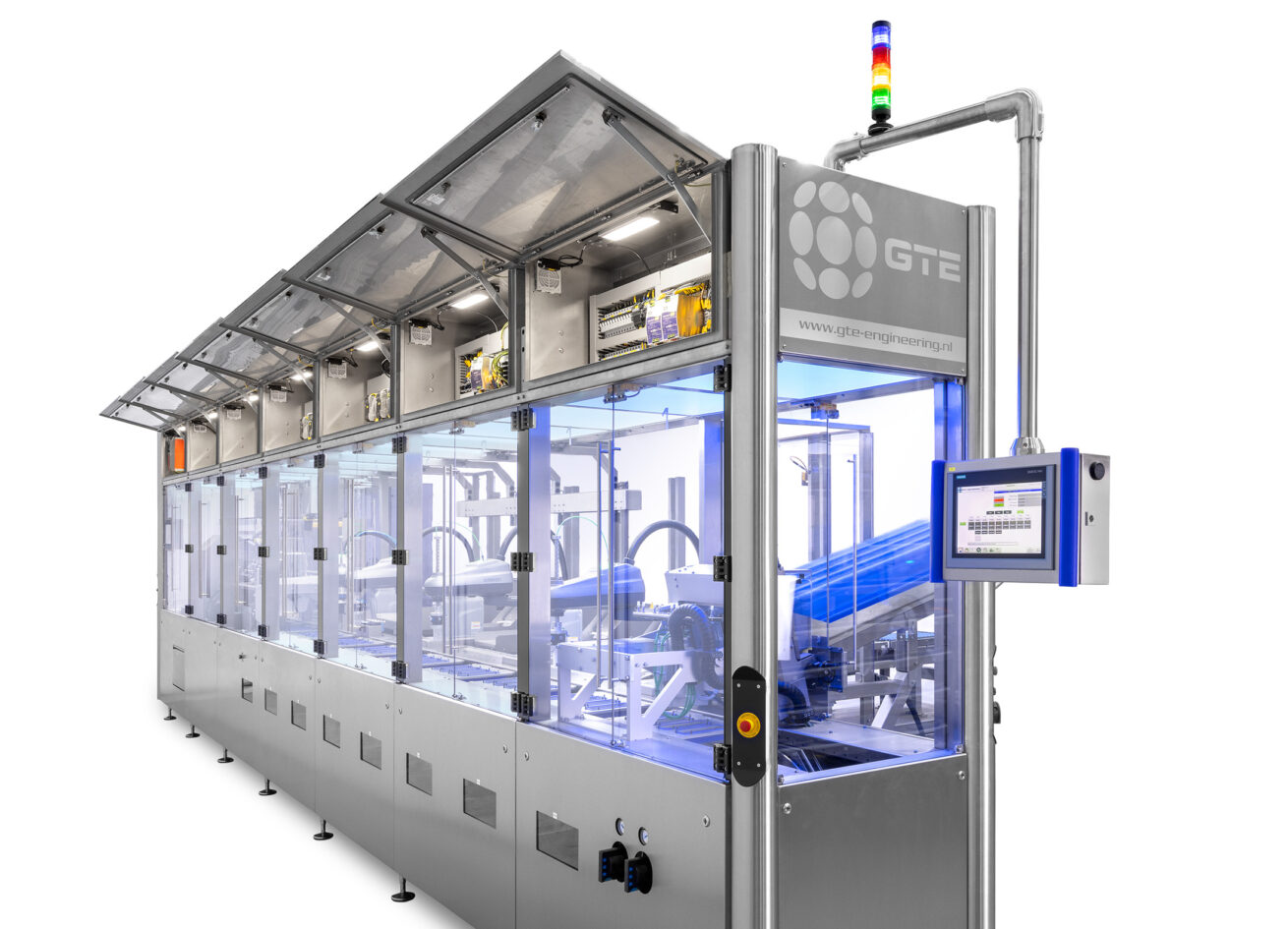

Easy Operation and Maintenance

The LAP-L blister filling and sealing machine features an intuitive control panel, making it easy to select different recipes. Additionally, the machine is equipped with docking stations, facilitating quick and straightforward maintenance and line clearance. This ensures that the machine remains accessible at all times with minimal downtime.

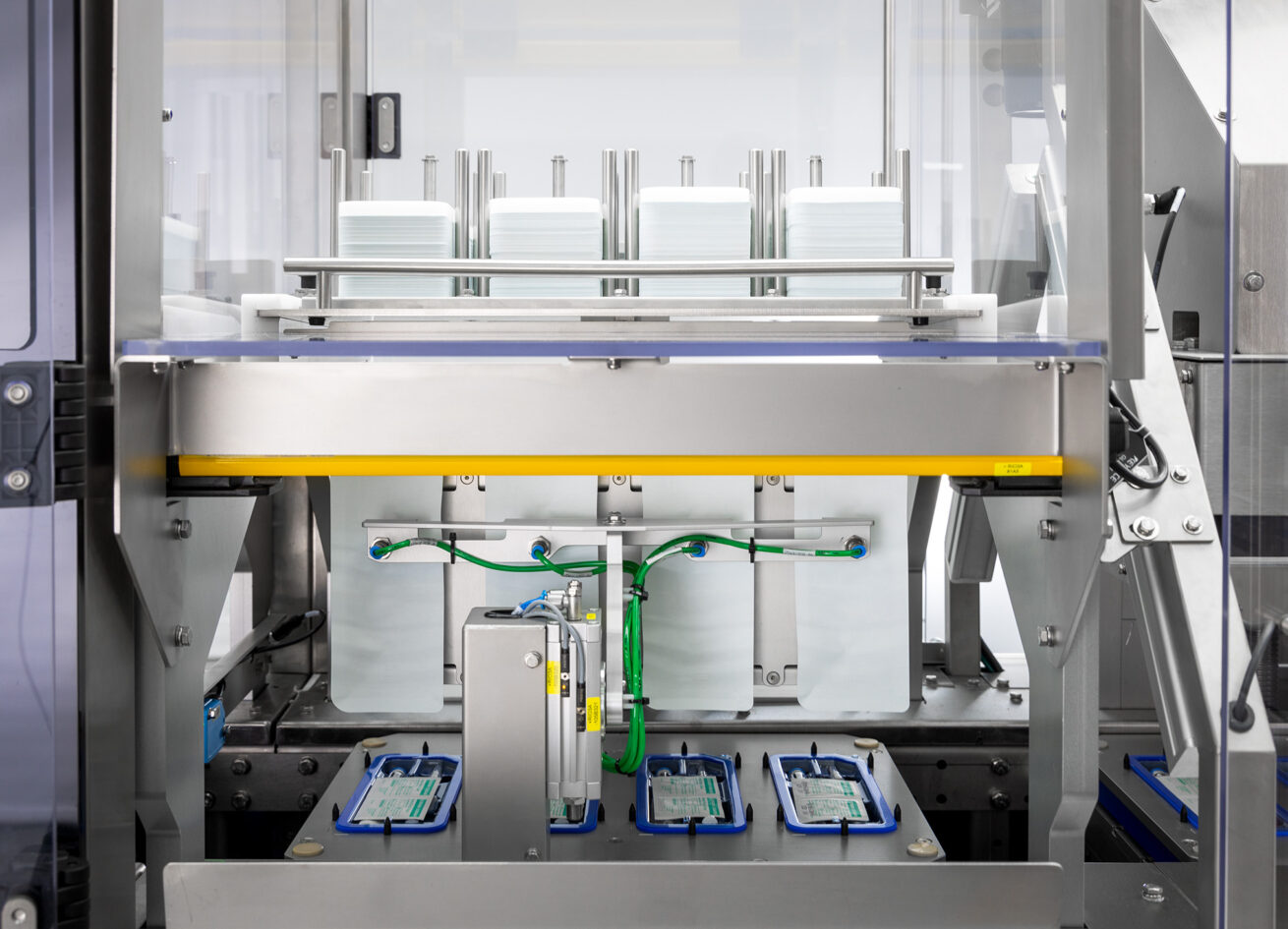

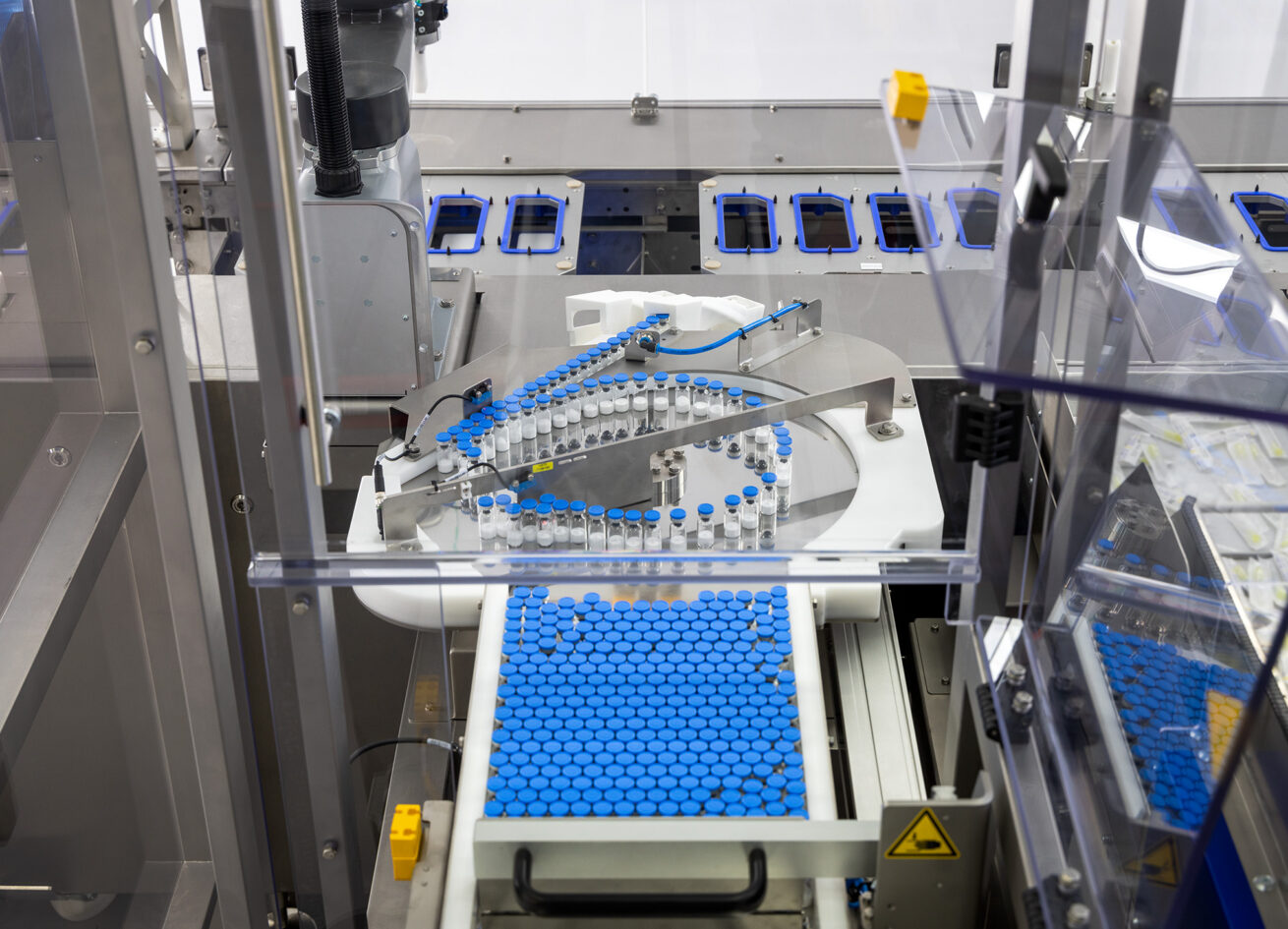

High Production Capacity

The LAP-L blister filling and sealing machine is designed for medium and high production volumes. With an impressive capacity of 1300 to 1500 blisters per hour, our clients can make their production processes more efficient and increase throughput.

Furthermore, the machine is fully automated and controlled by a reliable Siemens control system.

In conclusion, the LAP-L blister filling and sealing machine provides the ideal solution for the medical and pharmaceutical industry. With its flexibility, modularity, and high production capacity, this machine enables our clients to meet the strictest requirements and optimize their packaging processes.

Would you like to learn more about the LAP-L blister filling and sealing machine and how it can enhance your production? Please contact us for more information.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)