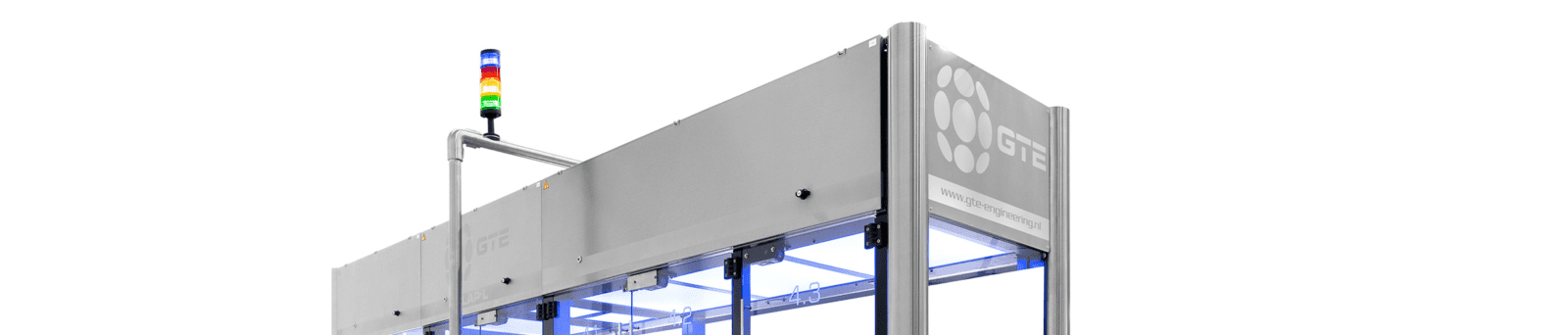

Completely modular

The platform primarily emphasizes modular scalability, enabling swift adaptation to customer requirements for expanding current machinery. Whether it’s augmenting existing systems or acquiring a brand-new LAP-L Platform, we ensure a relatively rapid delivery. This seamless integration within your organization ensures a swift Return on Investment, delivering expedient results.

Why GTE Platforms?

The GTE Platform is ideal for companies looking for a quick solution for their issues surrounding the automation of medical or pharmaceutical packaging and assembly processes.

Scaleable design

Are you in the start-up phase of your production line, but want to reserve the ability to expand with additional modules at a later date? The GTE Platform is fully designed to scale up later with additional modules and automate the production process even further.

Small footprint

It’s important to us to design machines that are as robust and foolproof as possible, while still having a small footprint. We achieve this by, among other things, placing E-cabinets above the machines.

Easy to maintain

It is precisely by placing the E-cabinets above the machines that maintaining them is easy and accessible. No more fumbling around in a far too cramped space behind, beside or at the bottom of the machine.

Controls

We use a Siemens S7-1500F fail safe PLC in our machines by default. The main benefit of this system is that this PLC has two separate networks, enabling you to connect to both the client network and the machine network – with different IP ranges.

Software

GTE doesn’t use 'locked software,' making it possible to adapt the software application to different formats and production recipes. Additionally, it’s possible to further automate the process at a later stage by adding additional modules.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

Fast ROI

With GTE Platform, you can count on a quick return on investment. Because the machine is designed based on your wishes and requirements, it’s guaranteed to do exactly what you want it to. Plus, we can guarantee the quality of our machine because we use high-quality components from our suppliers. Most of our machines will run for 20 years without any major problems. As a result, the return on your investment is quickly noticeable!

Looking for something different? Take a look at GTE Custom-Made!

Are you looking for a specific machine that hasn’t been listed on our website? Take a look at GTE Custom-Made! GTE Custom-Made is a line of machines designed for specific purposes and fully customised to your needs.

Discover our knowledge & inspiration

EcoVadis Silver rating

We are proud to announce that GTE Engineering has been awarded the EcoVadis Silver rating. This recognition confirms our commitment to sustainability, ethics, labour rights and responsible procurement. It is an important milestone that demonstrates our operations are structured, transparent and focused on continuous improvement.

Whitepaper: Everything about vision systems in the pharmaceutical and medical industry

Precision and accuracy are extremely important. Whether they are used for correctly labeling products, or verifying the integrity of packaging, vision systems play a crucial role in any production process. What are their strengths and limitations, how do you prepare for their implementation, and what will the future look like in terms of, for example, AI? We are happy to help you get started; download the free whitepaper!

The Importance of IQ, PQ, and OQ in Machine Construction for the Pharmaceutical and Medical Industry

In the pharmaceutical and medical industries, developing machines that meet the highest quality and regulatory standards is essential. Therefore, the steps of IQ (Installation Qualification), PQ (Performance Qualification), and OQ (Operational Qualification) are followed during the construction of these machines. These qualification tests ensure that machines meet the required standards for installation, operation, and performance, and they are a critical part of the validation process.

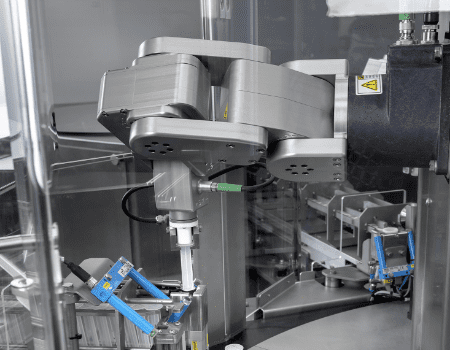

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)