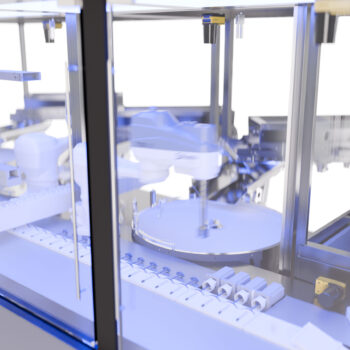

Scalable design with small footprint

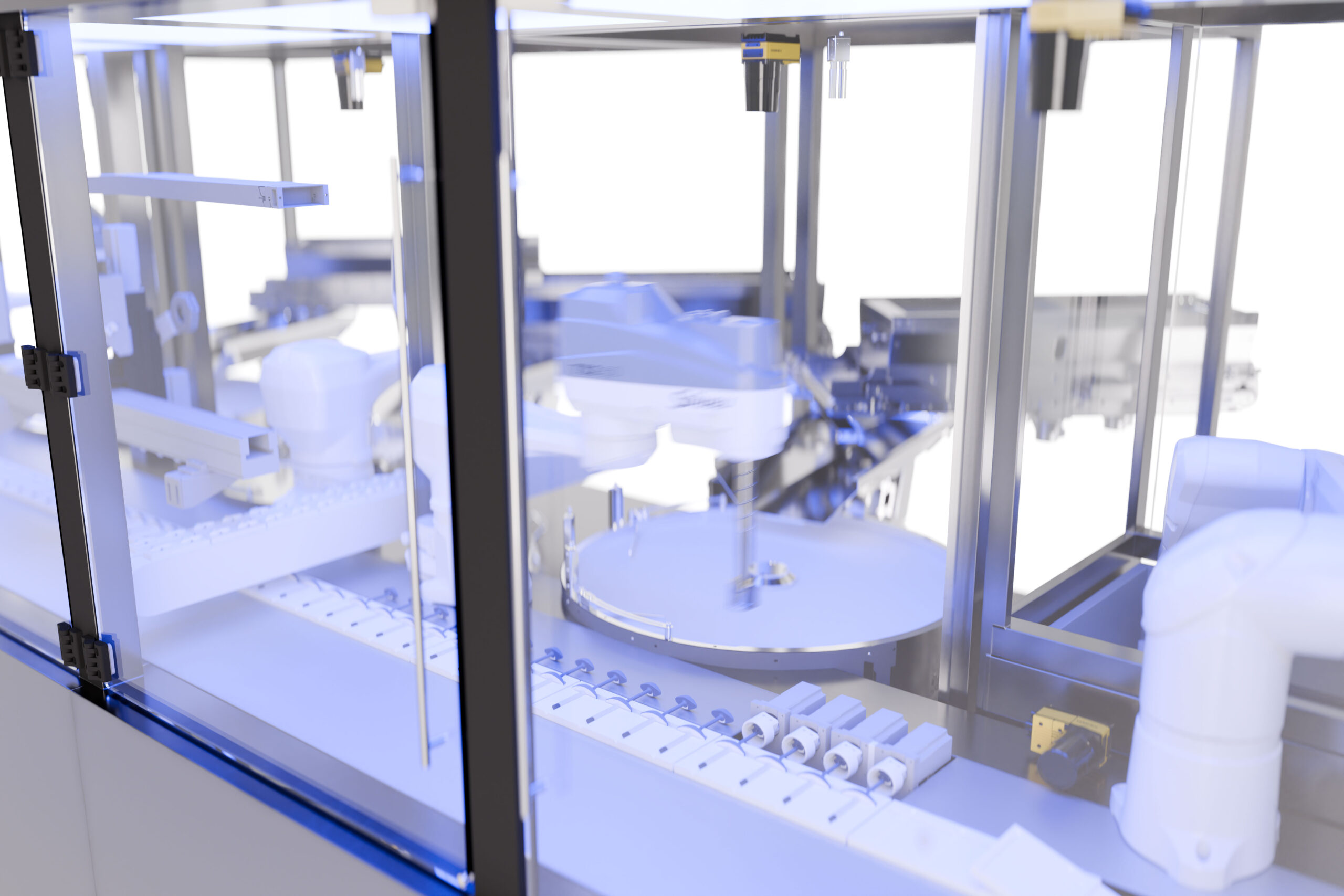

Our prefilled syringe assembly and labeling technologies offer a comprehensive range of solutions for both glass and plastic syringes, designed to meet diverse production needs. These solutions include:

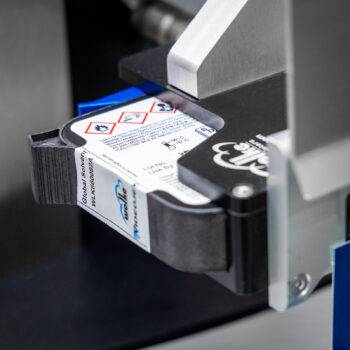

- Syringe body labeling: Accurate application of labels to the syringe body (Pagomat or Herma equipment integration)

- Backstop fitting: Secure attachment of backstops to syringes.

- Plunger rod insertion: Advanced modular insertion module for both screw and push-in assembly.

- Safety device insertion: Seamless insertion of syringes into safety devices.

Advanced options

In addition to these core functions, our systems can be equipped with advanced features to enhance operational efficiency and product quality:

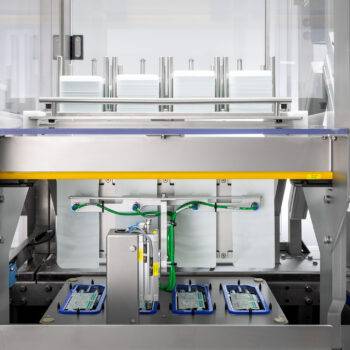

- Infeed tub or (WIP) tray buffering with FIFO Policy: Ensures the first-in, first-out processing of syringes, maintaining orderly production flow.

- Decoding of pre-printed data on the tub or tray by a vision system: Automated vision systems decode and verify data printed on tubs, ensuring traceability and reducing errors.

- Automated denesting from tub or tray: Efficiently removes nests from tubs to streamline the assembly process.

- Empty tub / tray and nest stacking units: Provides organized stacking of empty tubs and nests, facilitating continuous operation.

- Gentle transfer of syringes onto the unload guide: Ensures careful handling of syringes, reducing the risk of damage.

- Also available in no Glass-To-Glass contact version: Offers a version with no glass-to-glass contact, minimizing the risk of breakage and contamination.

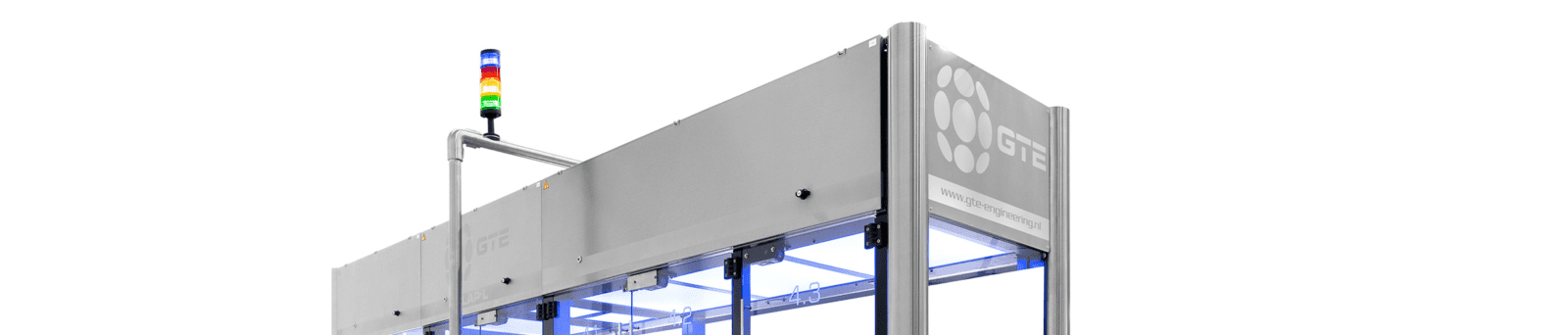

Why the SAP Platform?

The SAP Platform is, due to its small footprint and scalability, very suitable for companies that want to further automate a production, assembly or packaging process or for companies that are looking for a custom machine in a standardized platform with proven techniques. In addition to increasing capacity, the SAP platform can be used to perform process control and validation much better than, for example, a manual process.

Scalable Design

If you're looking for a platform that can be expanded later with additional modules or segments for syringe assembly, the SAP Platform is the ideal choice. The same technology is used in the SAP-M, SAP-S, and SAP models.

Precise en Consistent Assembly

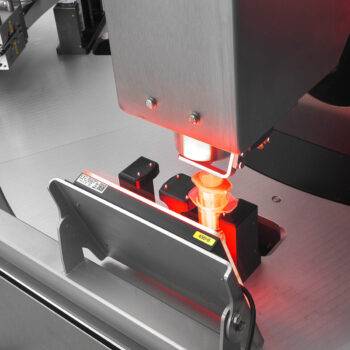

Furthermore, our systems can handle syringe plunger rod assembly through rotation or, for even greater accuracy, using torque-based assembly methods. This ensures precise and consistent assembly, meeting the highest standards of quality and performance.

Comprehensive Quality Control

At GTE Engineering, quality, consistency, and reliability are the primary focuses in the design of our machines. Our syringe assembly machines can be equipped with advanced vision systems to ensure these standards are met. These vision checks can detect incorrect assembly, verify proper product orientation, inspect labels, and assess print quality.

Control

Our machines are equipped with a Siemens control platform as standard, typically the Siemens S7-1500F fail-safe PLC, combined with a clean and intuitive HMI. Other control systems, such as Allen Bradley, can also be implemented if required.

Software

Thanks to modular software and a well-designed HMI layout, the machine operation is user-friendly yet highly customizable. This setup also allows for easy adjustments to the software application for different (new) product formats and production recipes. Additionally, the process can be further automated later by adding extra modules, and GTE always shares the source code with the customer at the time of purchase.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

Quick ROI

With GTE Engineering’s SAP Platform, you can expect a quick return on investment. By combining existing segments and modules that can be tailored to the customer’s needs, we achieve a fast delivery time. Together with our customers, we evaluate which process steps are most suitable for automation, always considering both the costs of automation and the potential labor savings. However, the focus isn’t solely on ROI; in some cases, the validation of the process is of critical importance to our customers.

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)