Customized to Your Needs

While the LAP-C Platform is a standard platform, the machine is fully customized to your preferences and requirements. This allows you to get started relatively quickly and further automate assembly and packaging processes within your company. It’s also possible to equip the LAP-C Platform with various change parts, enabling the assembly and packaging of different products on the platform.

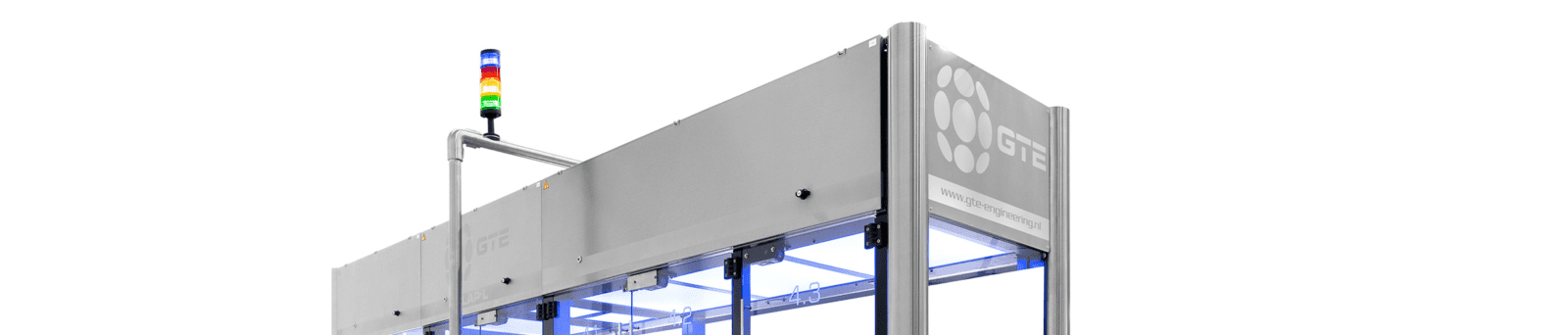

The LAP-C has a small footprint, achieved by efficiently utilizing the available space. This includes placing control cabinets above the machines. This not only reduces the machine’s footprint but also makes maintenance easier.

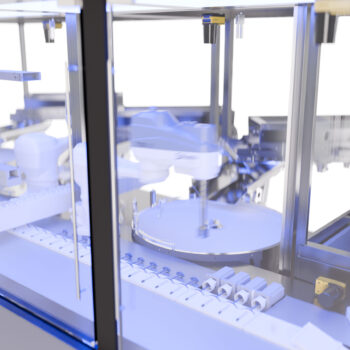

However, the LAP-C Platform is expandable and can be connected to other LAP-C, B, or L modules. Vibratory fillers and docking stations can be added to increase the level of automation and machine autonomy. Additionally, the platform is well-suited for the application of robots or cobots, enabling highly flexible and complex handling. The LAP-C comes standard with transparent safety enclosures featuring electronically lockable doors, ensuring maximum product visibility and the constant safety of employees.

How does the LAP-C Platform work?

GTE Engineering’s LAP-C Platform is a machine with a circular design, based on the LAP-L Platform. The difference between these two platforms is that the modules of the LAP-C Platform are positioned around the machine’s backbone. This reduces the platform’s footprint while maintaining accessibility to the so-called backbone.

The recognizable GTE design DNA is also integrated into the LAP-C, emphasizing a hygienic design suitable for cleanroom environments. The platform can optionally be equipped with its own fan-filter system for internal downflow.

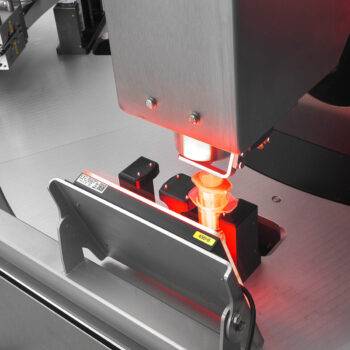

Control elements (emergency stops) are always recognizable and positioned within reach at the corners. The control screens on the HMI touchscreen have a distinct style. The modular design with high-quality stainless steel enclosures and frames makes the LAP-C an extremely durable machine in terms of lifespan, material usage, and recycling.

Advantages of the LAP-C Platform

The LAP-C Platform offers several unique features that showcase the knowledge and expertise of GTE Engineering:

- Scalable, modular design

- Adjustable work height for the operator(s)

- Operators have a clear overview of the entire machine

- Proven techniques from the LAP-L and LAP-B Platforms

- Highly accessible for maintenance and operators

- Suitable for small production quantities (high mix, low volume)

- Minimal footprint, can be lowered for transport

- Control based on Siemens, with the option for other systems

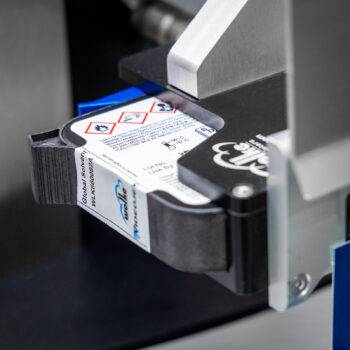

- Integration of Vision systems possible

- Shorter lead times compared to a fully custom machine

- Clear user interface, including status indication with LED panels in the machine’s ceiling

- Processes within the machine can be adjusted and expanded afterward

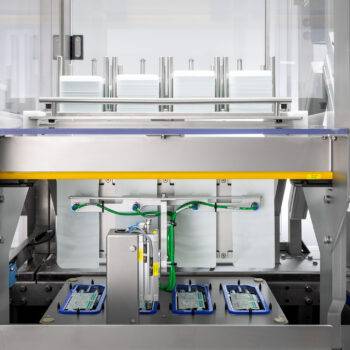

- PLC combined with remote IO stations to limit on-site installation and validation at the customer’s location

Why Choose the GTE Platform?

The LAP-C Platform, with its small footprint and the capability for robot and cobot integration, is highly suitable for companies looking to further automate their production, assembly, or packaging processes. It is also an excellent choice for businesses seeking a custom machine within a standardized platform with proven techniques. In addition to increasing capacity, the LAP-C significantly improves process control and validation compared to manual processes.

Scalable Design

If you're searching for a platform that can be expanded later with additional modules or segments, the LAP-C Platform is the ideal candidate. Adding docking stations further automates the production process. It's also possible to create a compact mobile solution with the relatively compact LAP-C machine design.

Small Footprint

During the design phase, the primary focus was on creating the most robust and foolproof machine possible with the smallest footprint. This was achieved by, among other things, placing control cabinets above the machines and setting up the basic design with modularity in mind. The machine is lowered for transport, allowing it to pass through a standard door height.

Easy Maintenance

Placing control cabinets above the machines makes maintenance easy and accessible. There's no need to work in tight spaces behind, beside, or under the machine. Thanks to easily removable panels, the mechanics, typically located below the product level, are highly accessible. The platform features remote access, making remote service easily achievable.

Control

Our machines typically use a Siemens control platform, often the Siemens S7-1500F fail-safe PLC, combined with a clean and user-friendly HMI. Other control systems, such as Allen Bradley, can also be implemented.

Software

With modular software and a well-thought-out HMI layout, machine operation is clear yet highly adjustable. This modularity allows you to later adapt the software application to different (new) product formats and production recipes. Moreover, it's possible to further automate processes by adding extra modules at a later date. Upon purchase, GTE always shares the source code with the customer.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

Quick ROI

With GTE Engineering’s LAP-C Platform, you can count on a rapid return on investment. By combining existing segments and modules that can be customized to the customer’s requirements, we achieve a quick delivery. We work with our customers to determine which process steps are most suitable for automation, considering both automation costs and potential labor savings. However, the focus isn’t solely on ROI; in some cases, process validation is crucial for our customers.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields