Key benefits of the BAP-C Rotary Sealer

- Easy to operate: The BAP-C features an intuitive user interface, making it simple for operators of all skill levels to use.

- Low maintenance: Built with durable components, the BAP-C requires minimal maintenance, reducing your operational costs.

- Maximum productivity: Achieve higher throughput with the BAP-C’s simultaneous printing and sealing capabilities.

- Minimizing owntime: Designed for quick and easy tool changes, the BAP-C ensures your production line keeps moving.

- Safer and better ergonomics: Enhanced safety features and ergonomic design provide a safer working environment for your team.

- Future proof: With upgradeable modules, the BAP-C is prepared to meet your future needs.

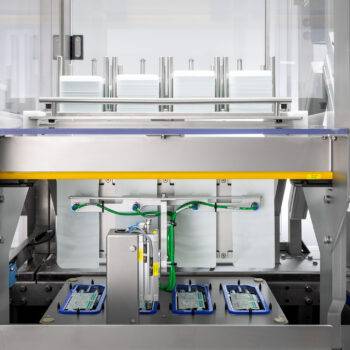

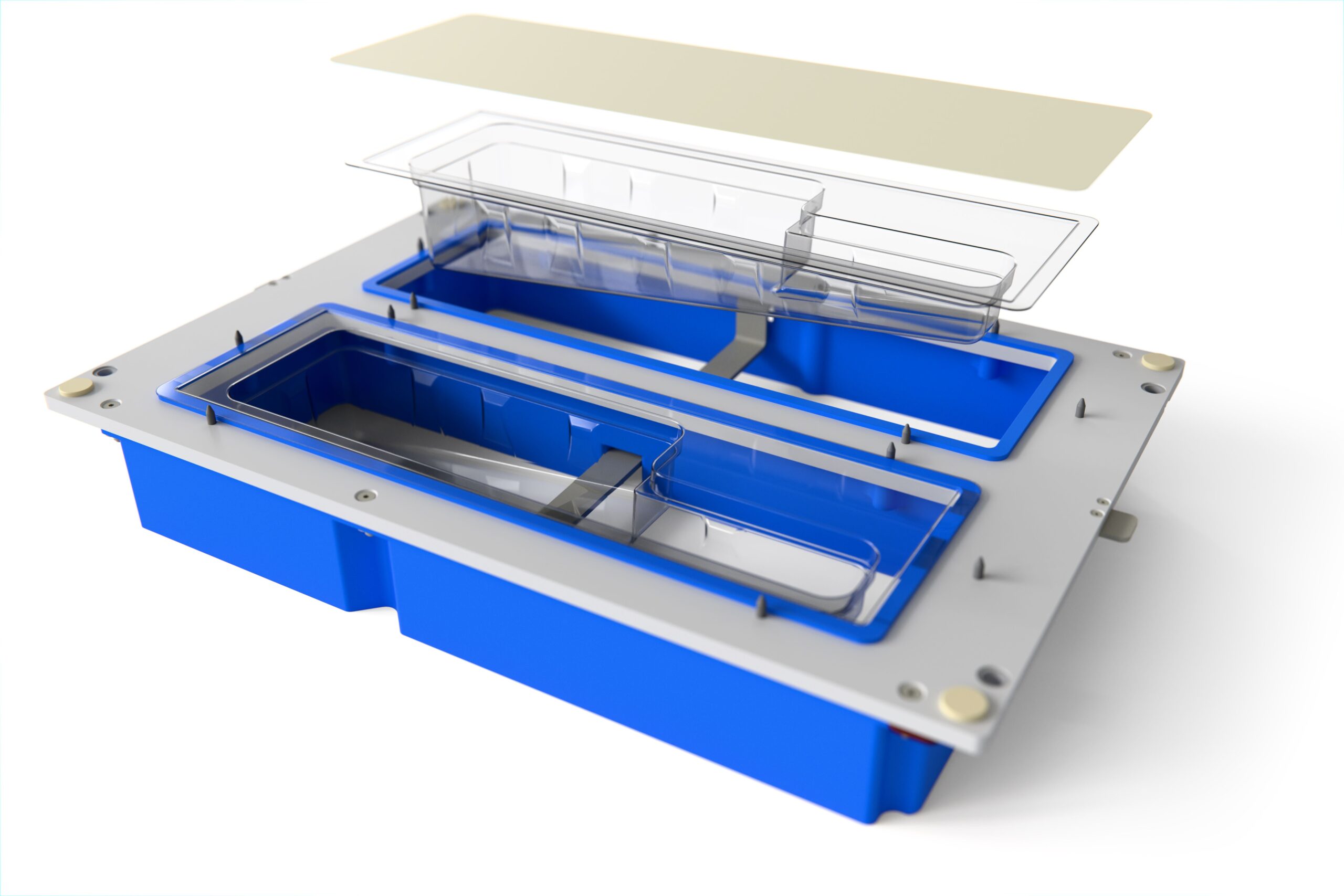

- Large sealing molds: placing more blisters in one mold, allowing for increased output.

Specifications

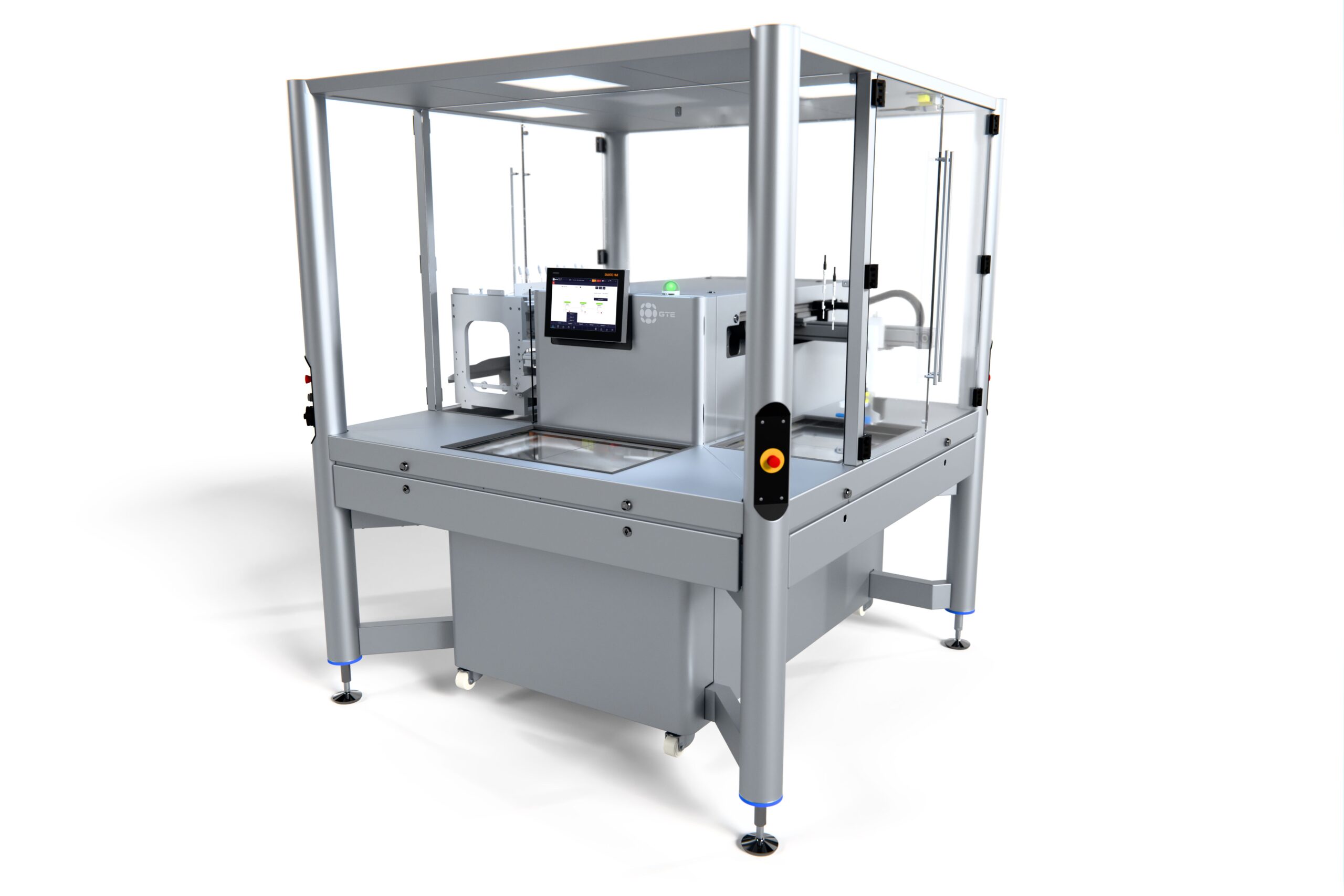

- Durable construction: The BAP-C boasts a stainless steel frame and covers, ensuring longevity and robustness.

- Ergonomic design: Includes ergonomic shelf space for easy placement of products or trays.

- User-Friendly interface: Equipped with a Siemens TP1200 touchscreen for a seamless user experience.

- Safe mould cover mechanism: Automatic mould cover mechanism enhances safety during operation.

- Cleanroom compatibility: Class 7 cleanroom compatible, making it suitable for sterile environments.

- Automatic pushers: Facilitates easy tray removal with automatic pushers.

- Convenient operation: Start the seal cycle with a push button or set a timer for automated operation.

- Quick tool changes: Designed for easy and fast tool changeovers to minimize downtime.

- Separated components: Pneumatic and electric components are separated for enhanced safety and maintenance.

- Data logging: Logs seal force, temperature, and seal time during each cycle for quality assurance.

- Custom built: Custom-built sealing dies and heat plates tailored to your specific needs.

- Automation ready: Prepared for further automation to enhance your production capabilities.

Why the BAP-C

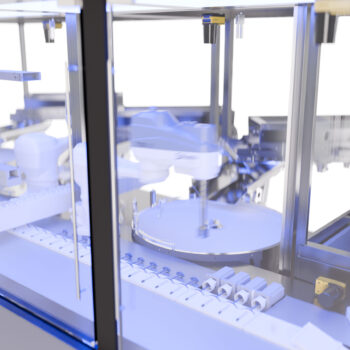

The BAP-C Platform is, due to its small footprint and scalability, very suitable for companies that want to further automate a production, assembly or packaging process or for companies that are looking for a custom machine in a standardized platform with proven techniques. In addition to increasing capacity, the BAP-C platform can be used to perform process control and validation much better than, for example, a manual process.

Scalable design

If you're looking for a platform that can be expanded later with additional modules or segments for blister sealing, the BAP-C Platform is a good choice for starters. It's prepared for further automation.

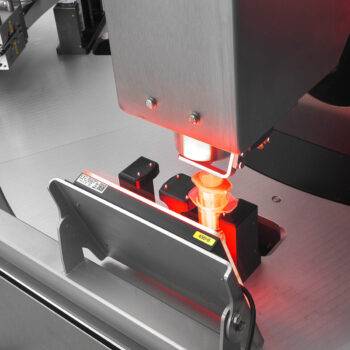

Comprehensive quality control

At GTE Engineering, quality, consistency, and reliability are the primary focuses in the design of our machines. Our BAP-C rotary sealer can be equipped with advanced vision systems to ensure these standards are met. These vision checks can verify proper product orientation, inspect labels, and assess print quality.

Control

Our machines are equipped with a Siemens control platform as standard, typically the Siemens S7-1500F fail-safe PLC, combined with a clean and intuitive HMI. Other control systems, such as Allen Bradley, can also be implemented if required.

Software

Thanks to modular software and a well-designed HMI layout, the machine operation is user-friendly yet highly customizable. This setup also allows for easy adjustments to the software application for different (new) product formats and production recipes. Additionally, the process can be further automated later by adding extra modules, and GTE always shares the source code with the customer at the time of purchase.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

Optional features

- Height adjustable frame: Customize the height of the frame to suit your operational needs.

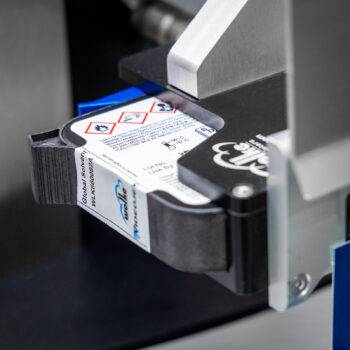

- Variable data printing: Print variable data via a thermal inkjet printer for enhanced traceability.

- Multiple operator positions: Accommodates up to three operator positions or stations for increased efficiency.

- Advanced automation: Ready for advanced automation, including:

- Cobot blister handling

- Infeed magazine for blisters and lids

- Lid printing

- Automatic insertion/applying of labels and IFUs

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)