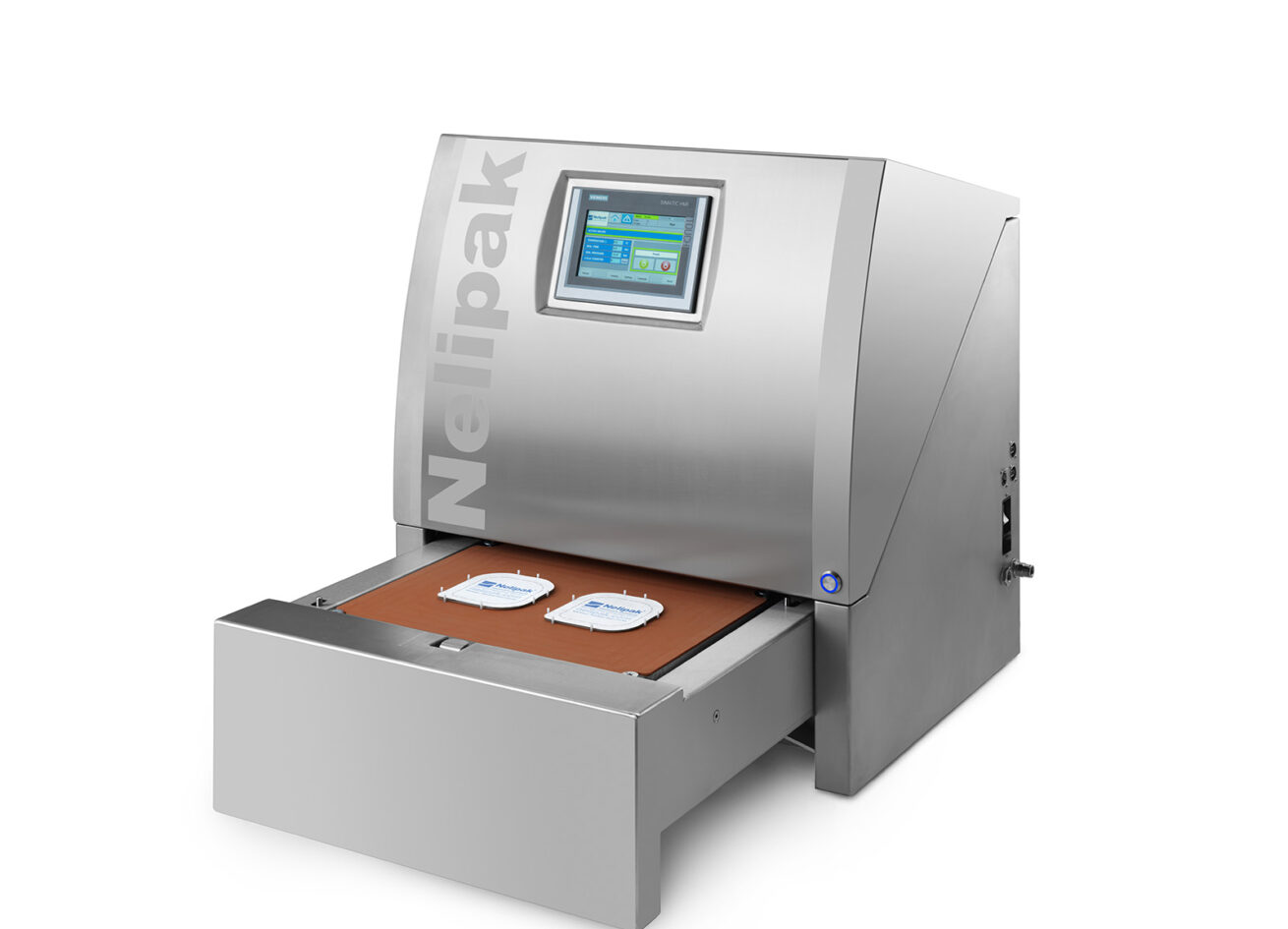

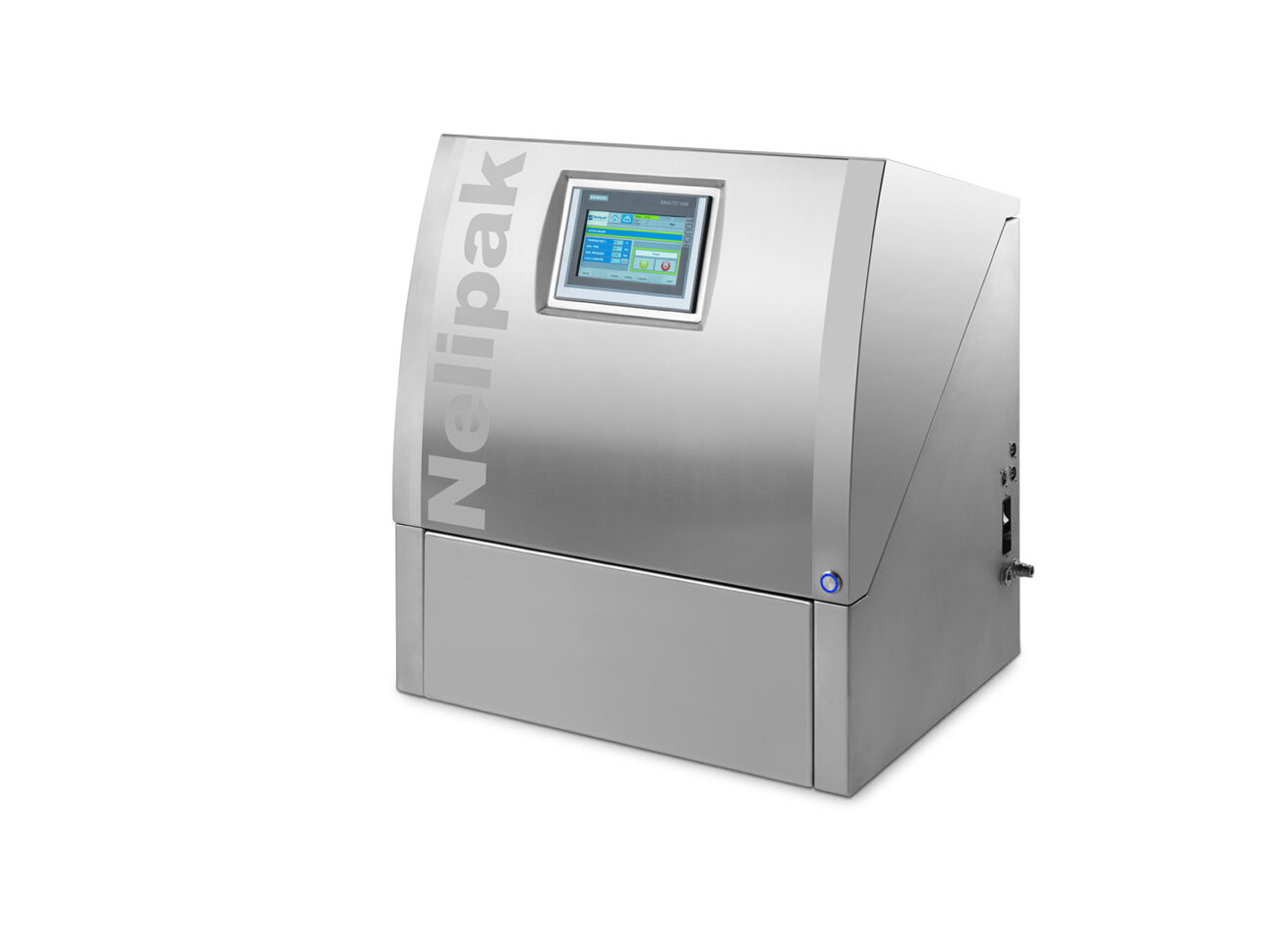

Differences from regular Sealing machines

The Sealing machine with an automatic drawer has a bigger range of functionalities compared to the regular Sealing machine. The Sealing machine with an automatic drawer, for example, has RFID (Radio Frequency Identification) used to detect the right-sized parts, Class 7 Cleanroom Certification, an automatic extruder to easily swap out trays, 21 CFR 11 registration, registration of seal strength and pressure during production cycles, and separated pneumatic and electrical parts for ease of maintenance. In short, the Sealing machine with an automatic drawer is the “smarter” and more efficient sibling of the regular Sealing machine.

Specifications

- RFID to detect right-sized parts

- Flexible because of easy-to-change trays

- 21 CFR 11 Registration

- Class 7 Cleanroom certification

- Quality control by recording seal pressure and strength

- Easy to maintain

Requesting assets

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)