The process

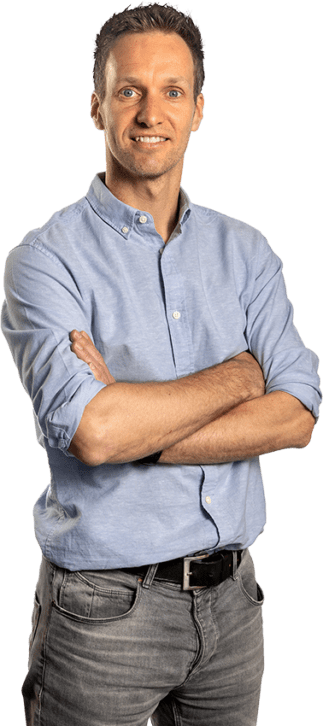

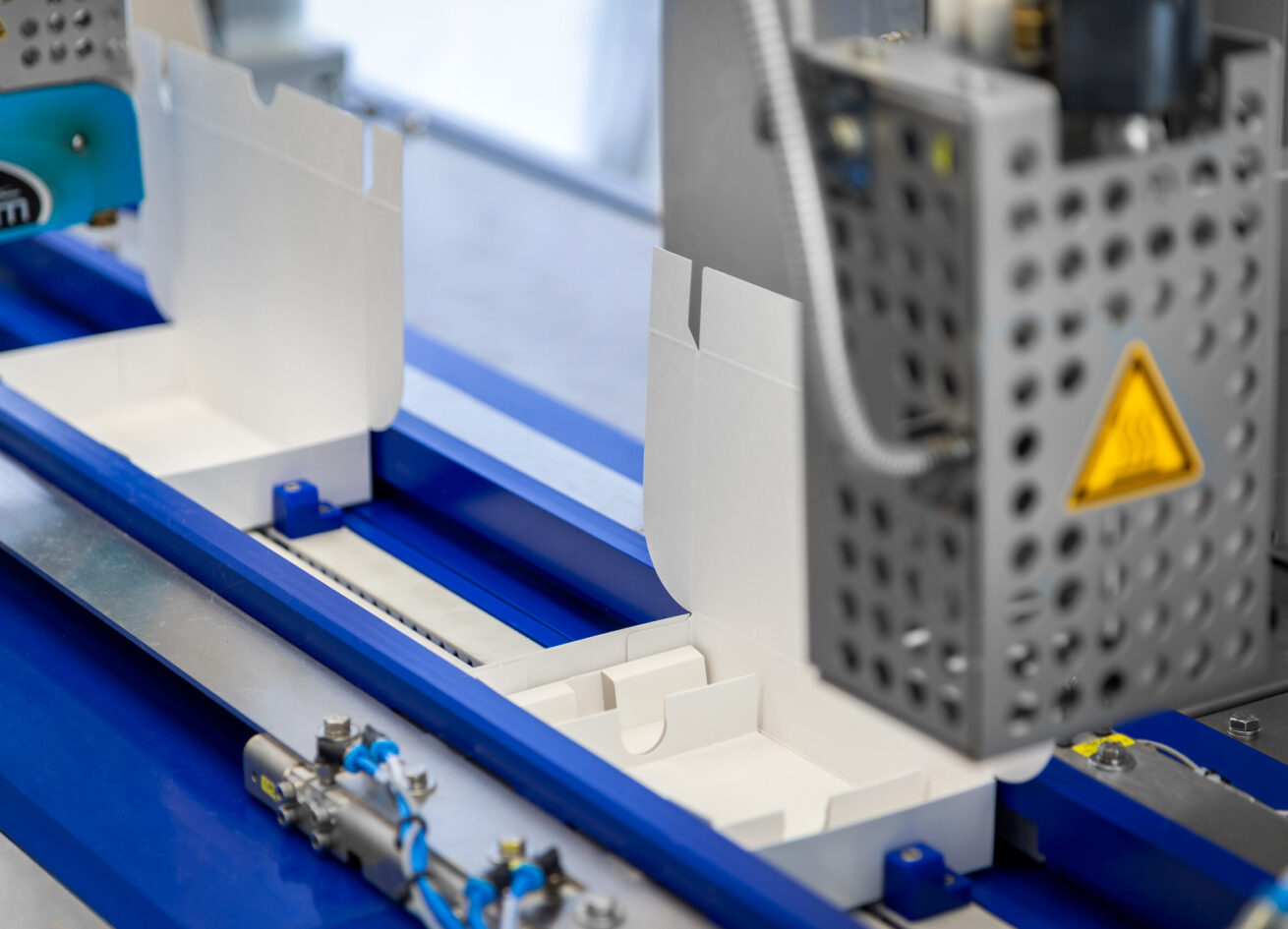

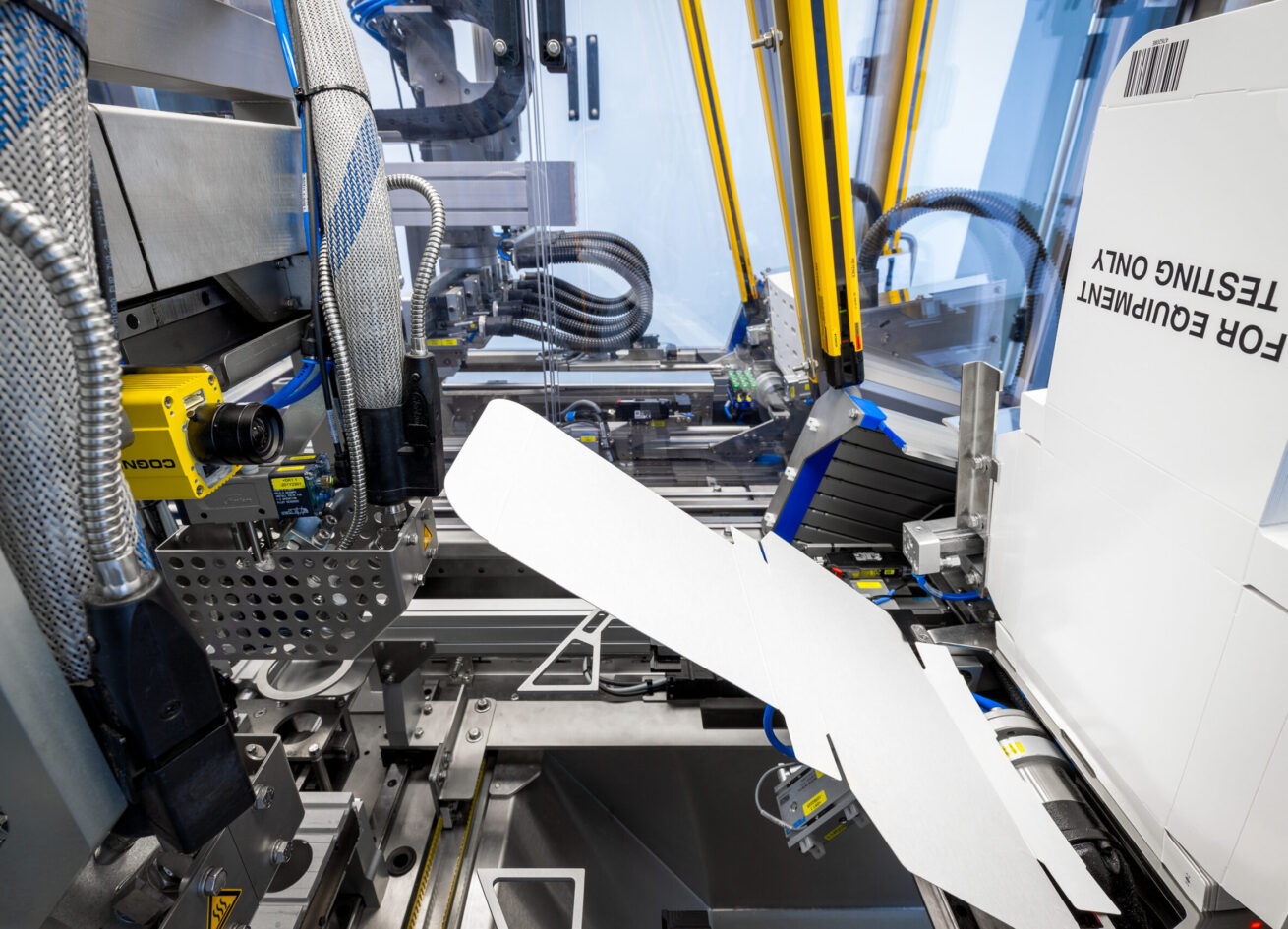

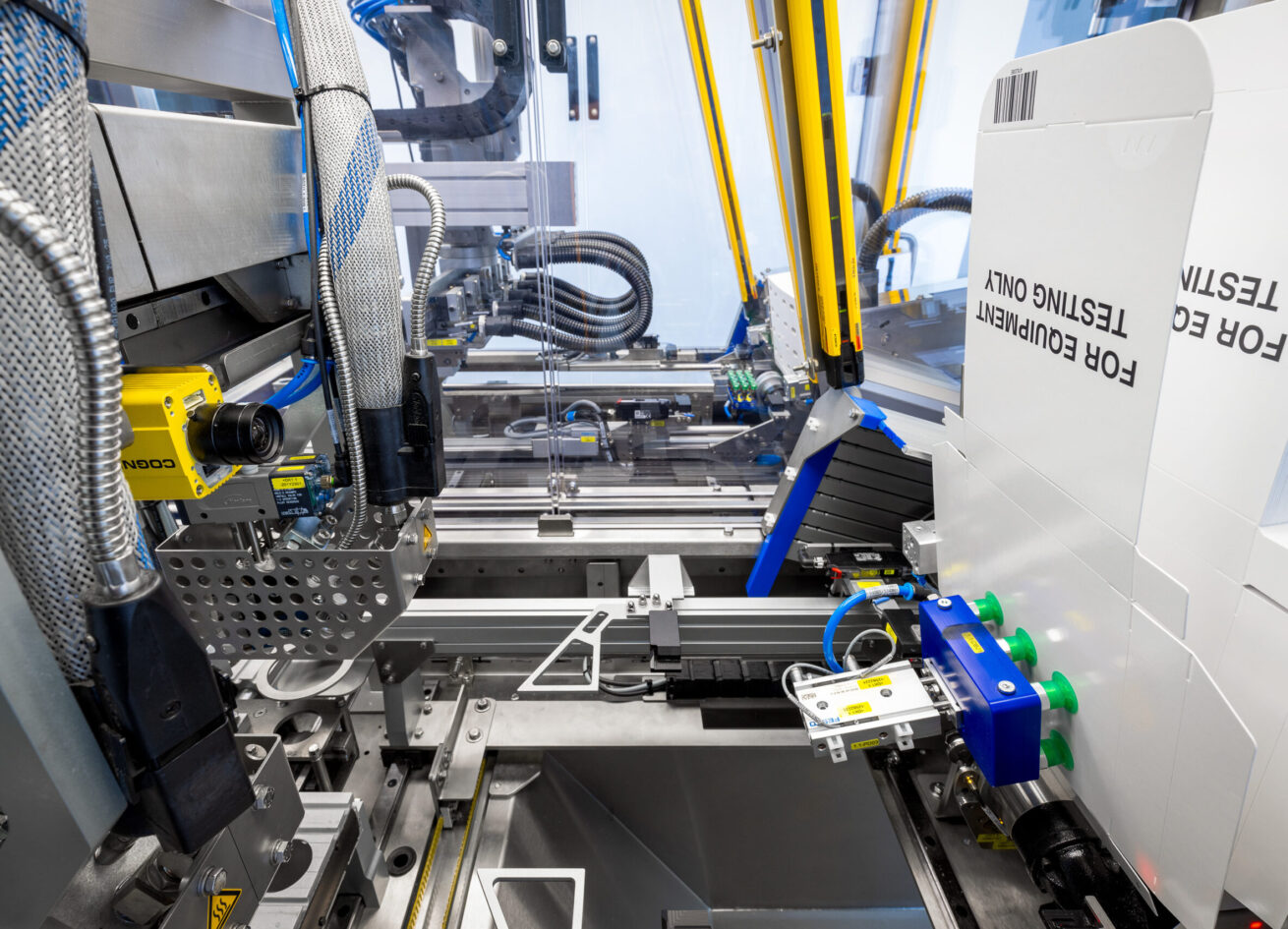

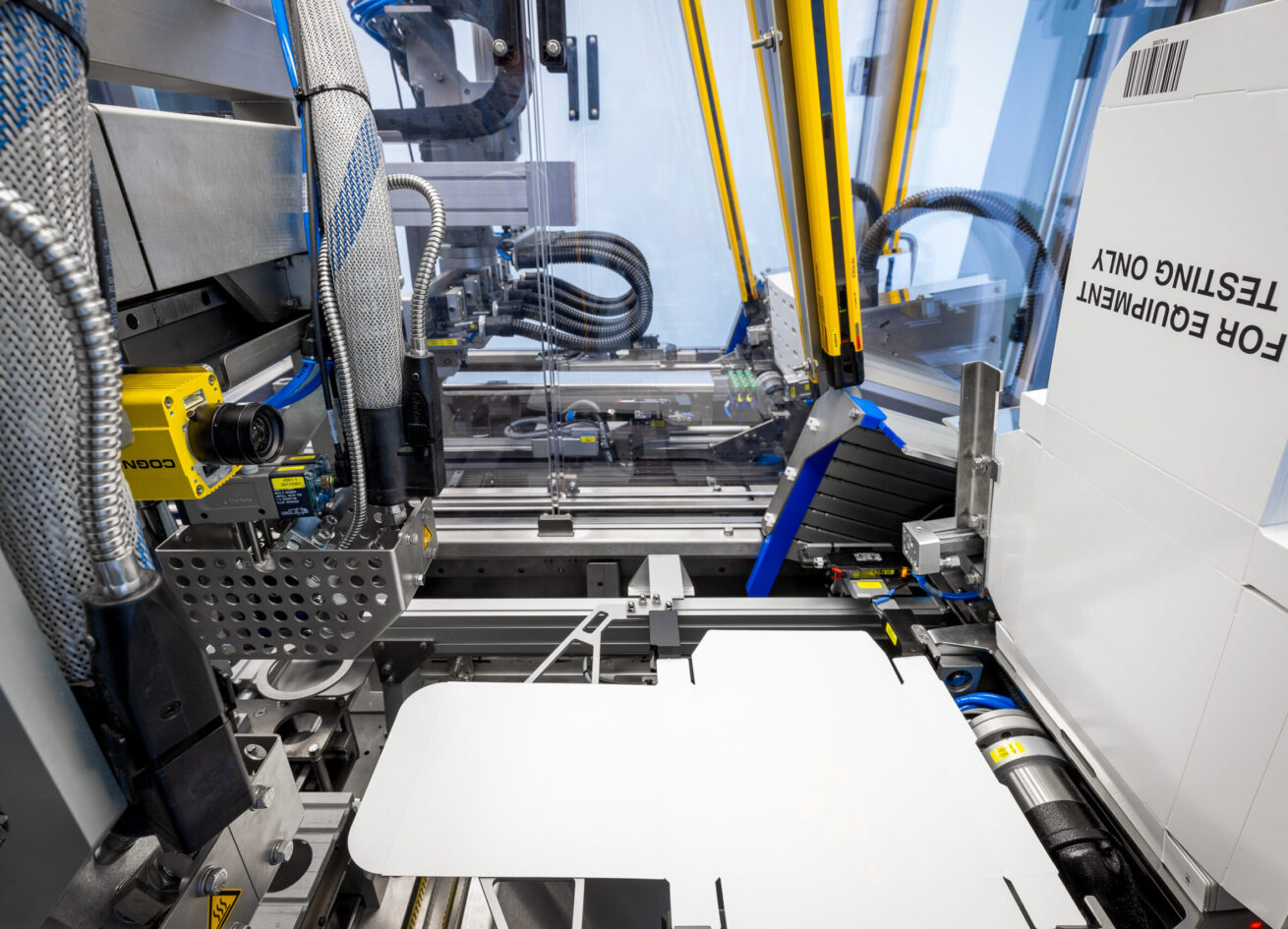

This machine is ideal for high-mix, low-volume production, delivering the same high quality as high-speed machines but with significantly more flexibility. The LAP-L allows you to switch to a different box size in just 15 minutes, thanks to its automatically adjustable molds and tool-free format change. This makes the machine highly versatile and suitable for various box sizes and inlays/partitions. Additionally, the ability to refill magazines during production ensures a continuous and efficient workflow.

The LAP-L is fully automated and operates based on pre-set recipes, featuring a Siemens control system integrated with HMI functionality in the LED lighting. It is designed for both tuck-in and overlap lid boxes, with a production capacity of 20-25 boxes per minute.

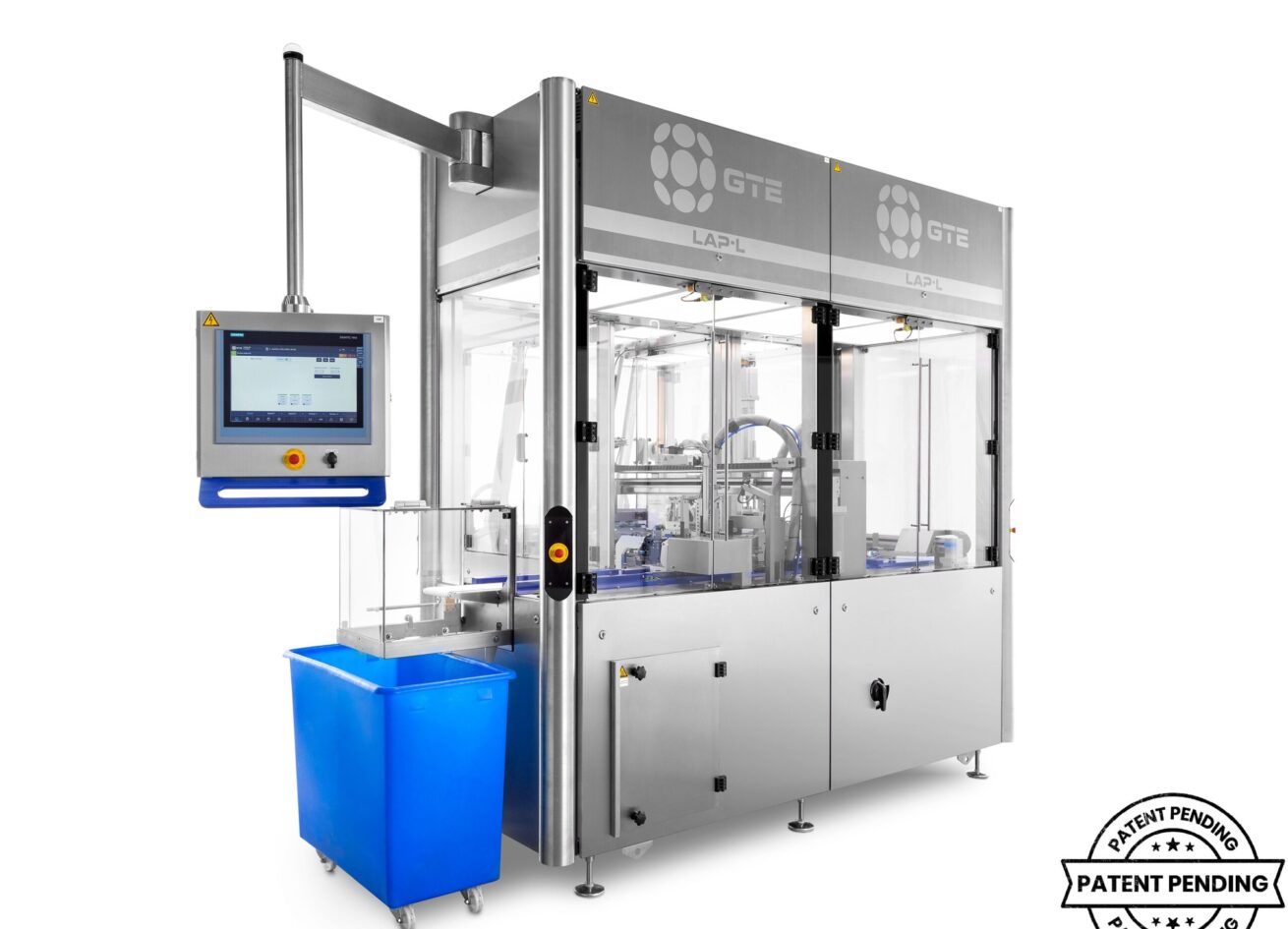

Furthermore, the machine’s modular design allows for easy expansion with filling and sealing modules, vision checks, and labelers. Its compact footprint makes it space-efficient, while the user-friendly HMI screens and color-coded LEDs provide clear status updates.

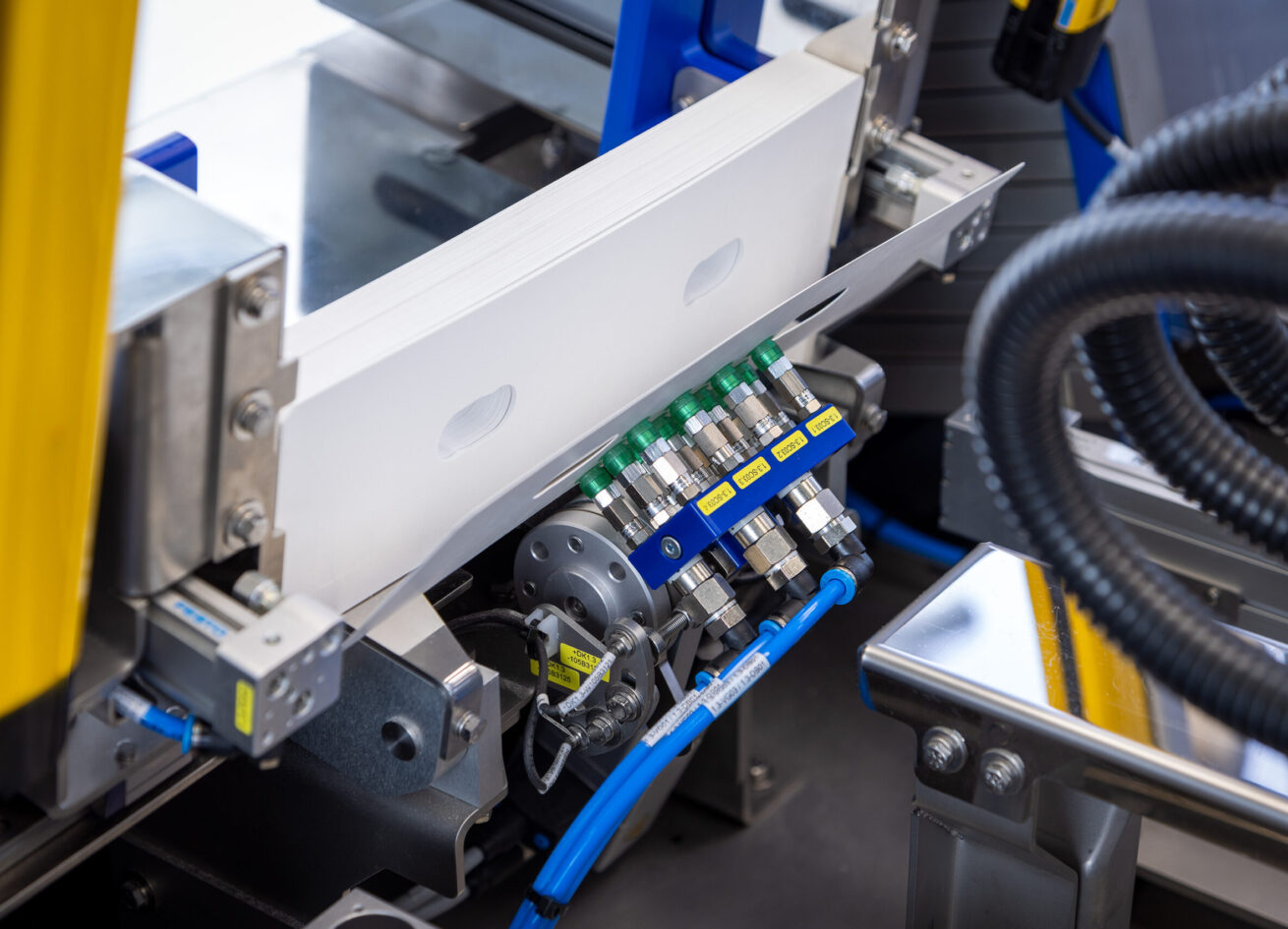

With features like barcode/data matrix verification, a hot melt glue system, and easy maintenance, the LAP-L offers an innovative and reliable packaging solution. The unique, automatically adjustable molds, for which a patent is pending, add to the exclusivity and advanced capabilities of this machine.

Medium speed top load cartoning Machine specifications:

- Unique automatically adjustable molds (patent pending)

- 20-25 boxes per minute

- Minimum and maximum box sizes:

- Minimum: 65 x 45 x 25 mm (LxWxH)

- Maximum: 180 x 160 x 40 mm (LxWxH)

- Refillable magazines during production

- Modular linear machine: expandable with filling and closing modules, vision checks, and labelers

- Compact design with a small footprint

- User-friendly HMI screens and color LEDs for status indication

- Barcode/datamatrix verification

- Hotmelt glue system

- Based on the LAP-L platform

- Easy maintenance access

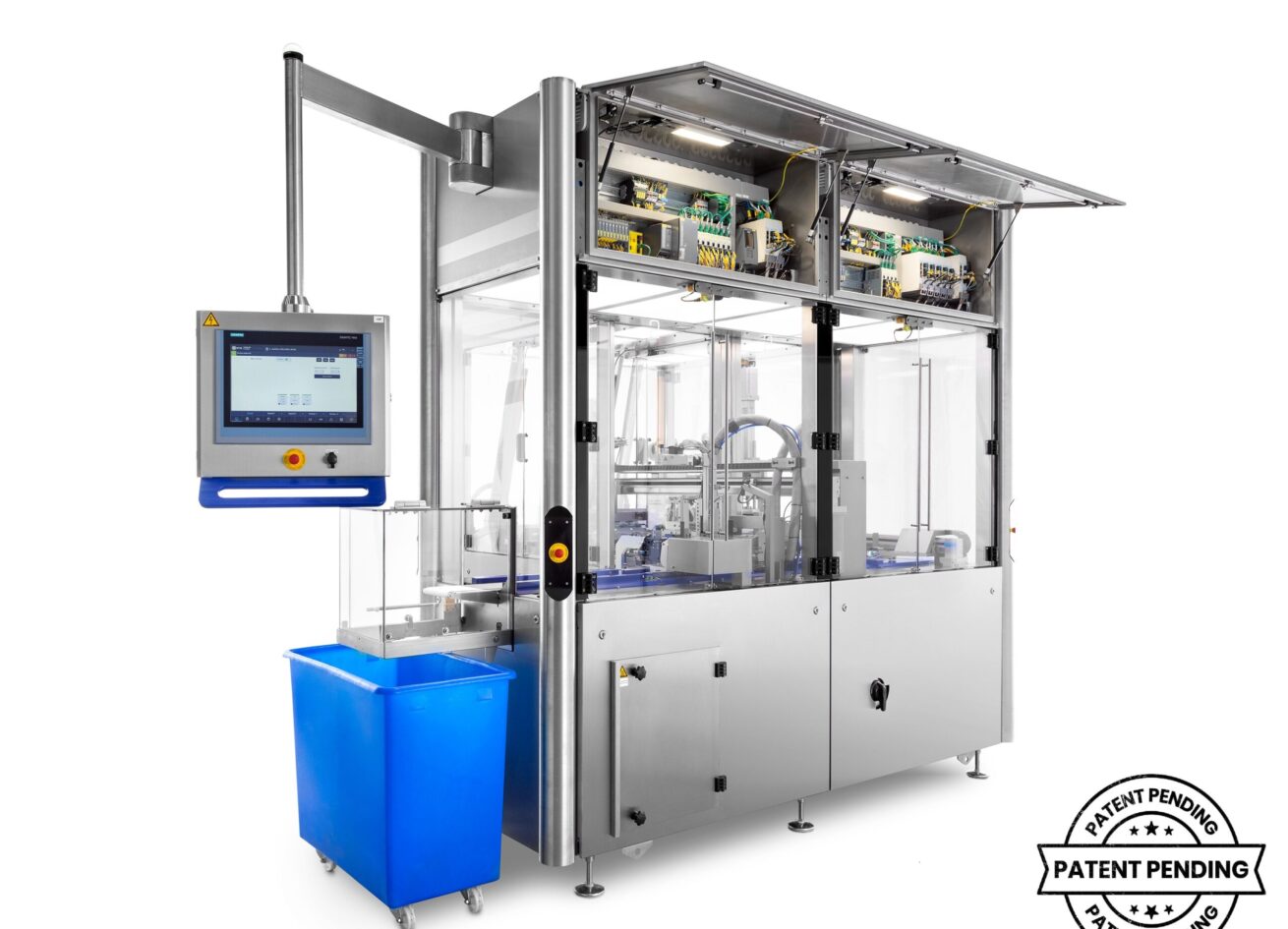

Get more information

Wondering how the Machine could be useful for your organisation? Request more information using the form below.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our solutions can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)