How the liquid filling machine works

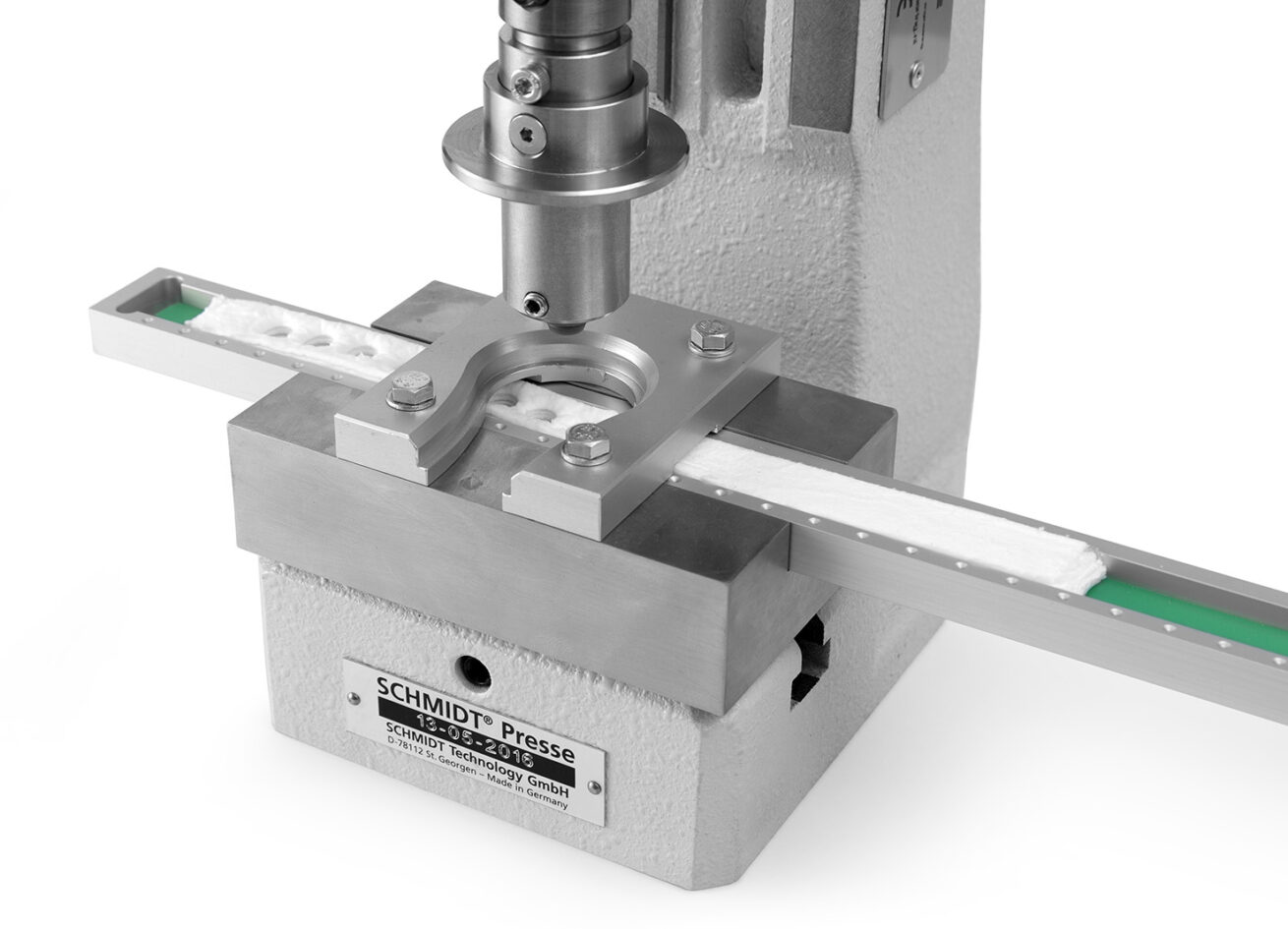

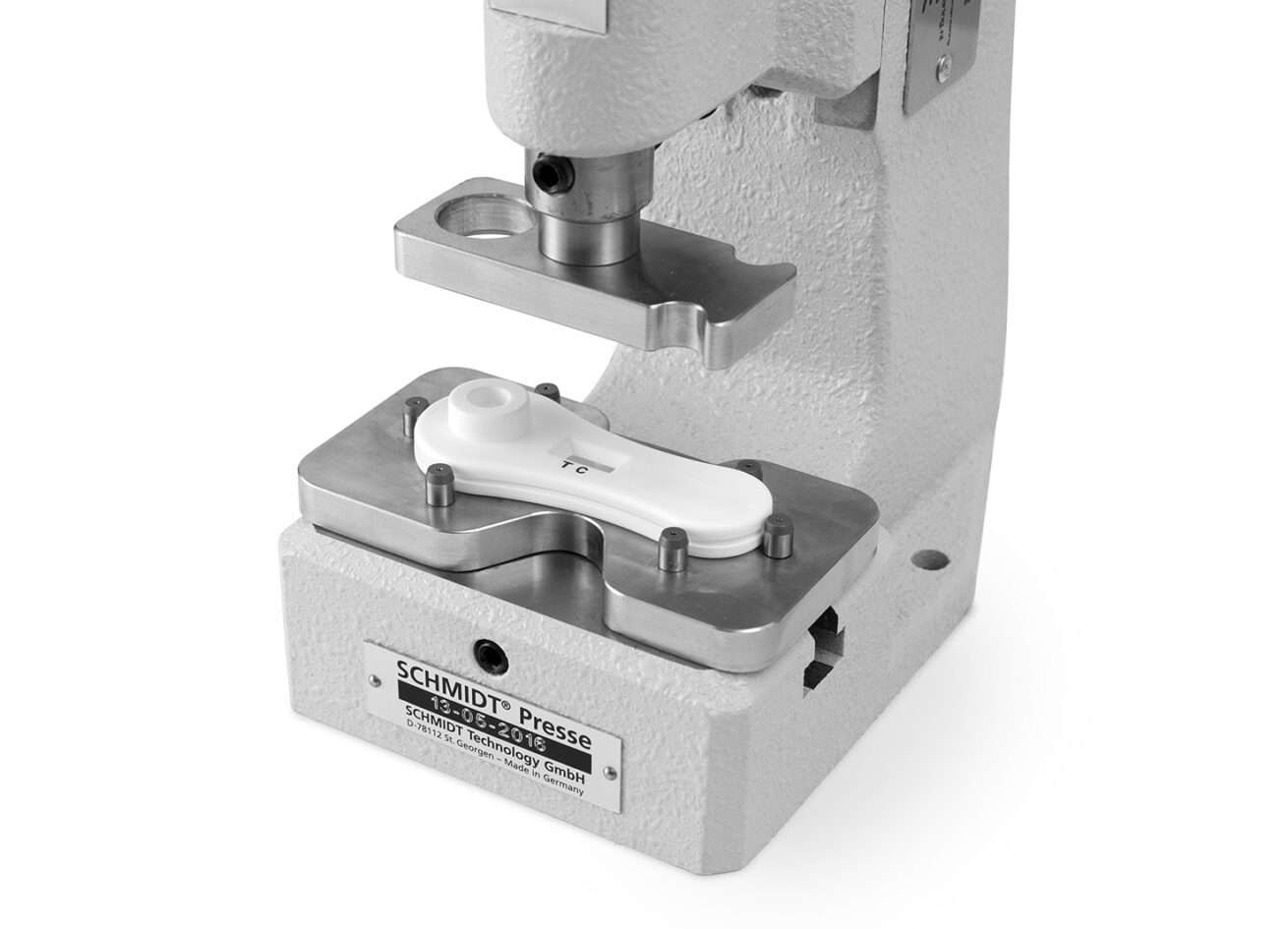

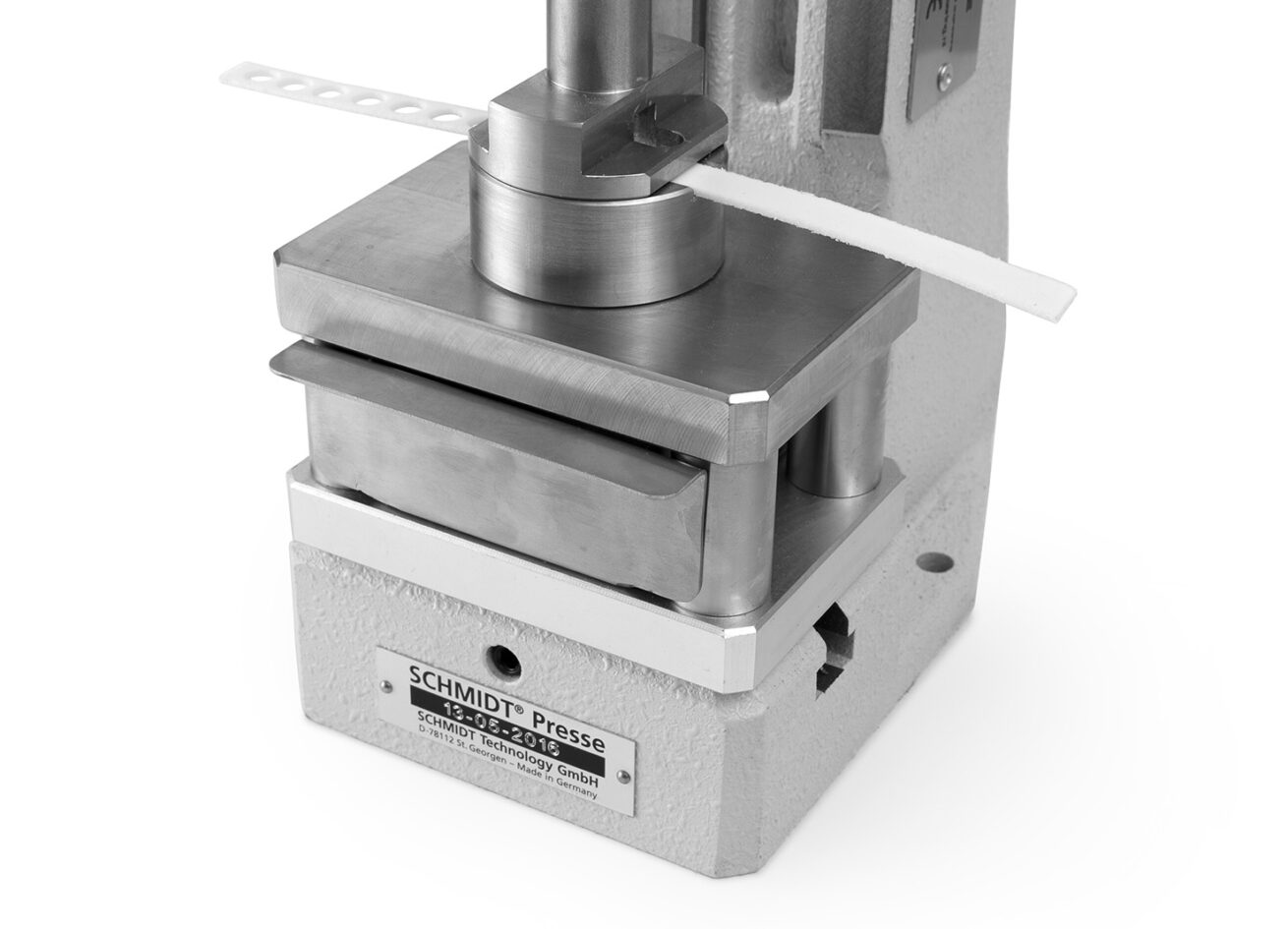

The filling machine starts by dispensing liquid with a remarkable accuracy of 0.01 ml (10 µL). This high level of precision ensures that the desired amount of liquid is administered, which is crucial for consistency and quality in various applications. Next, you manually add a component, which is pressed on with the force and height appropriate for your packaging and product. This step requires human intervention to place the component in the correct position. The pressing force and height are carefully controlled to ensure proper integration with the product. Once the liquid and component integration are completed, the machine seals the carefully punched aluminium foil onto the product. The machine allows for easy adjustment of various parameters to optimize the sealing process. Operators can set parameters such as seal temperature, pressure, and time. These settings are crucial for tailoring the process to the specific requirements of the packaging and the nature of the product.

Specifications liquid filling machine

- Simplifies precision work

- Assembles in a validated manner

- Semi-automatic: ideal for clinical trials

- All-in-one solution for filling, assembling, punching, and sealing

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)