A station-by-station breakdown

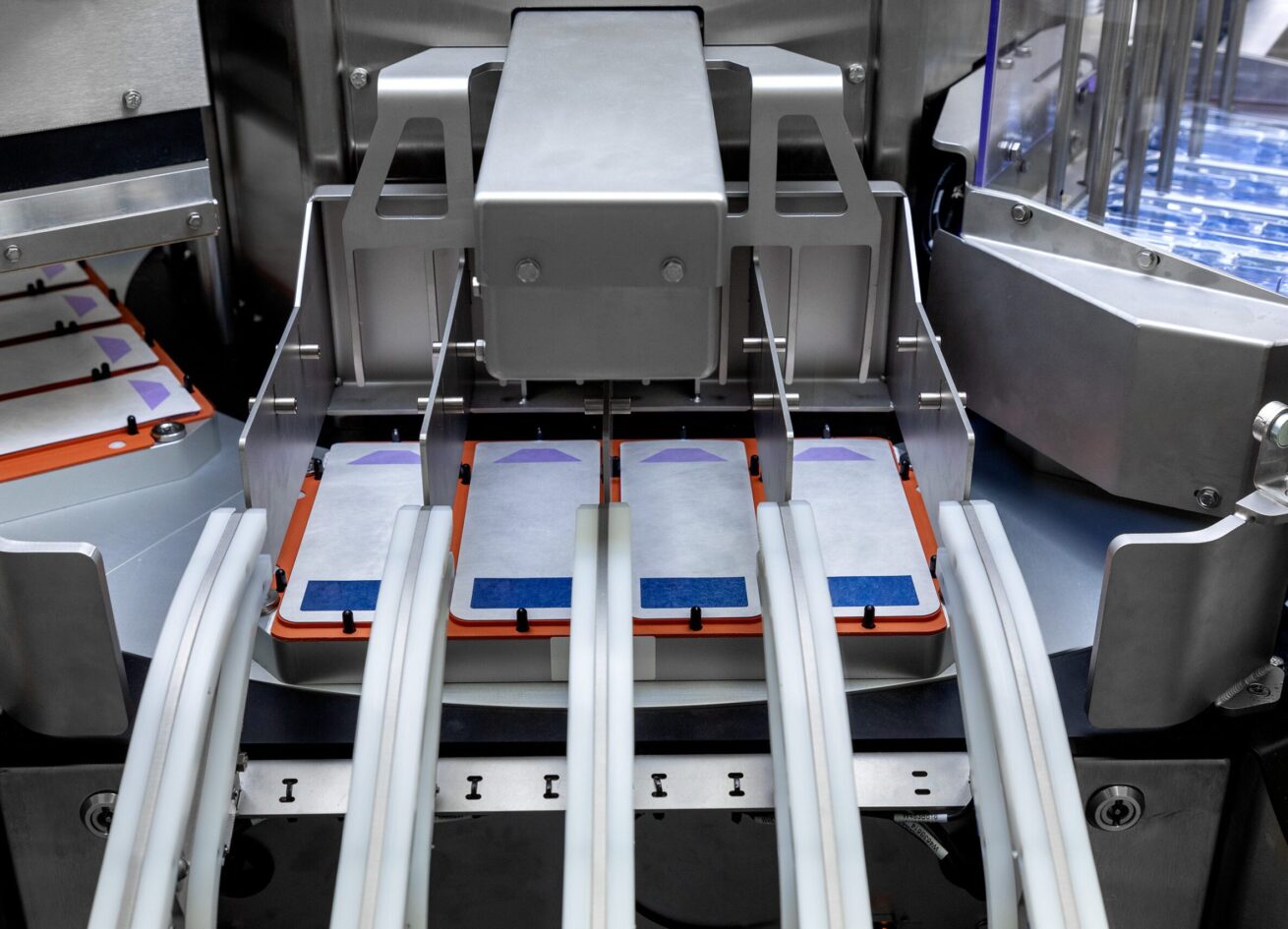

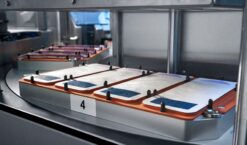

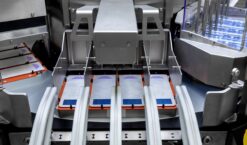

Station 1: The blisters are automatically placed in the quadruple mold from a warehouse.

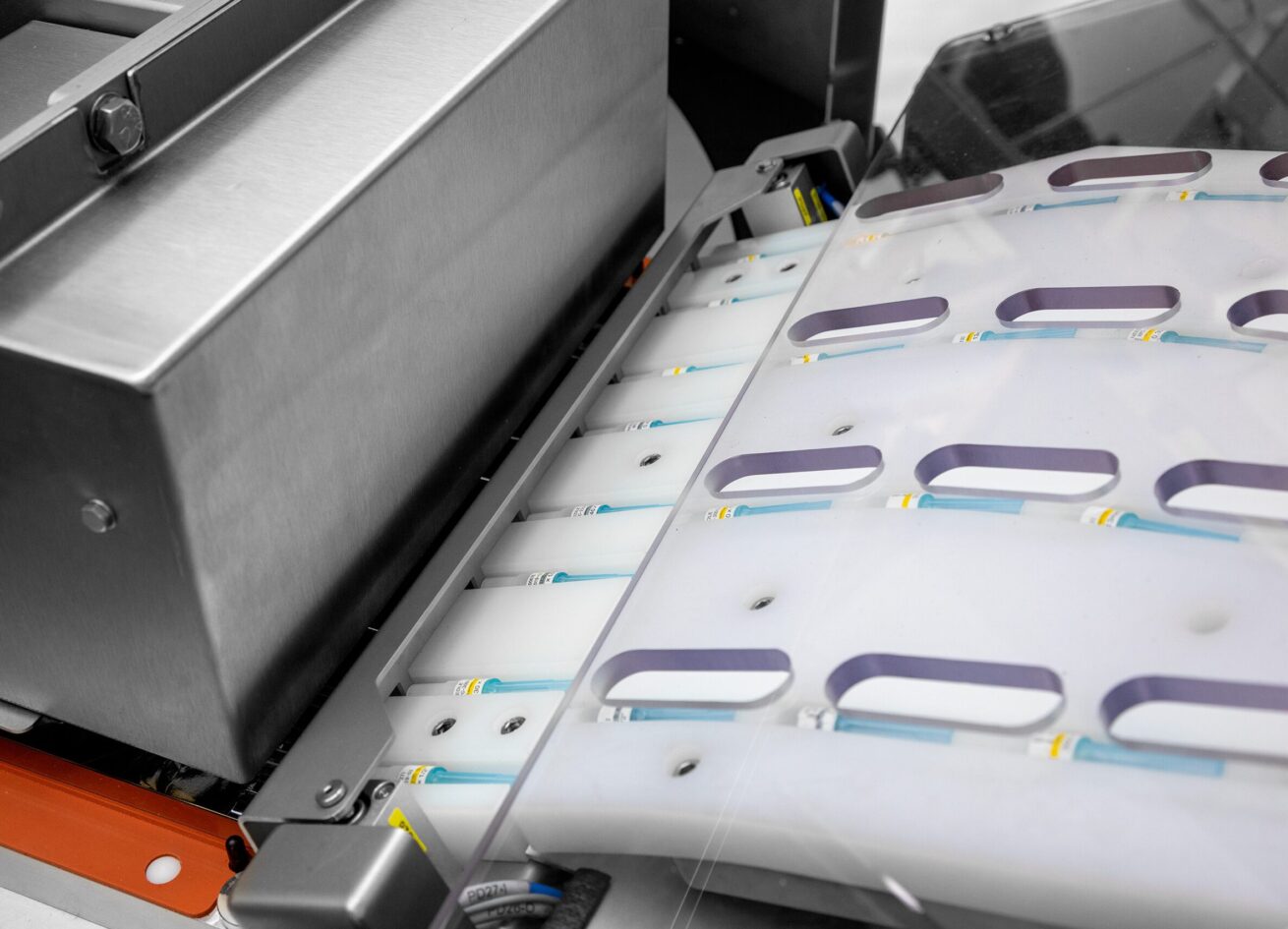

Station 2: The syringes are manually placed in a chute, then automatically placed in the blister. Of course, this manual step can also be replaced with automation. Ideal for, for example, larger quantities or creating a buffer in the supply process.

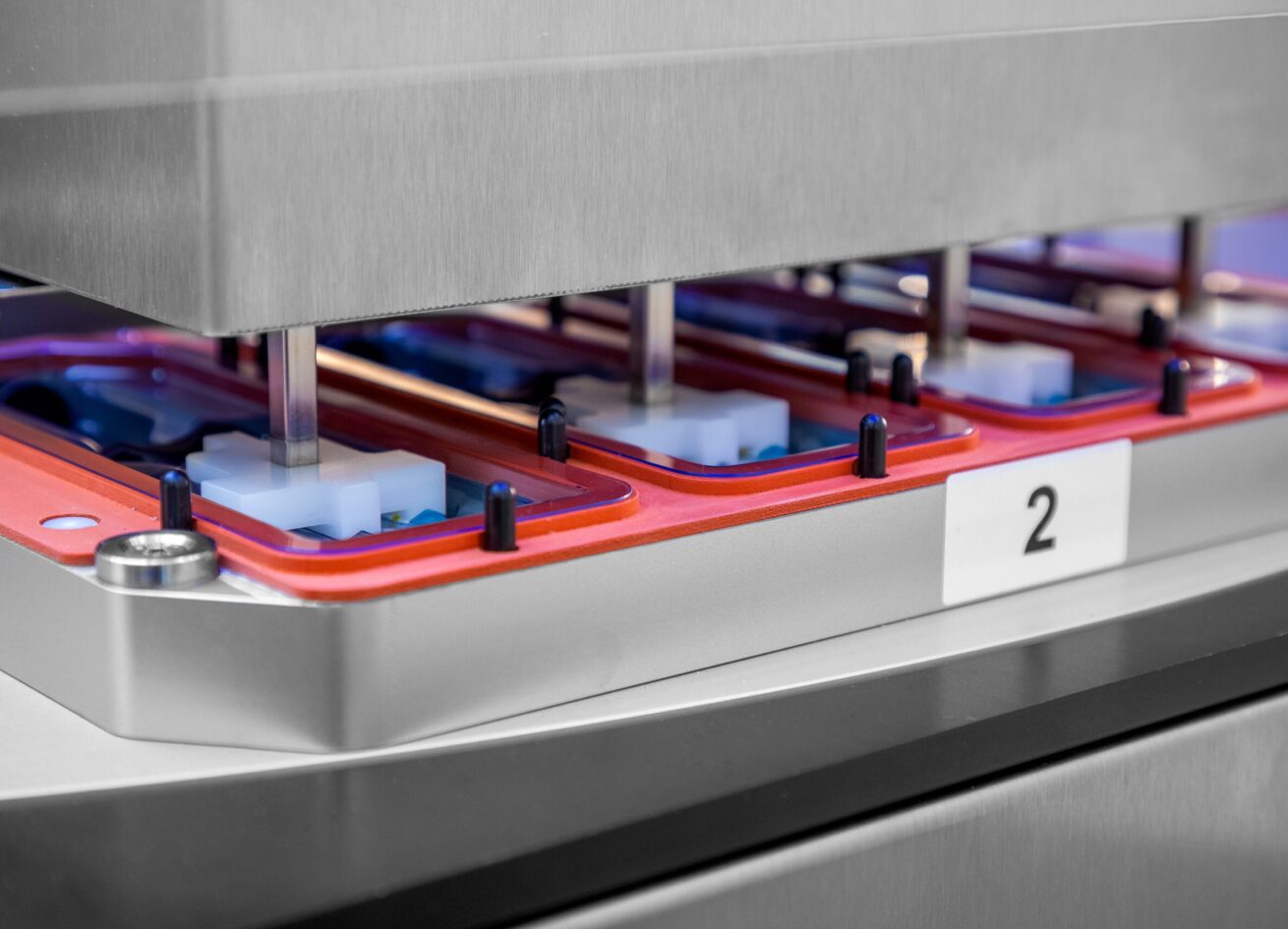

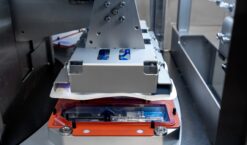

Station 3: The safety-wrapped needles are separated and aligned in the correct direction via a vibratory filler. The needles are then placed two by two in the blisters. The needles and the syringe are pressed into the blister with a set force.

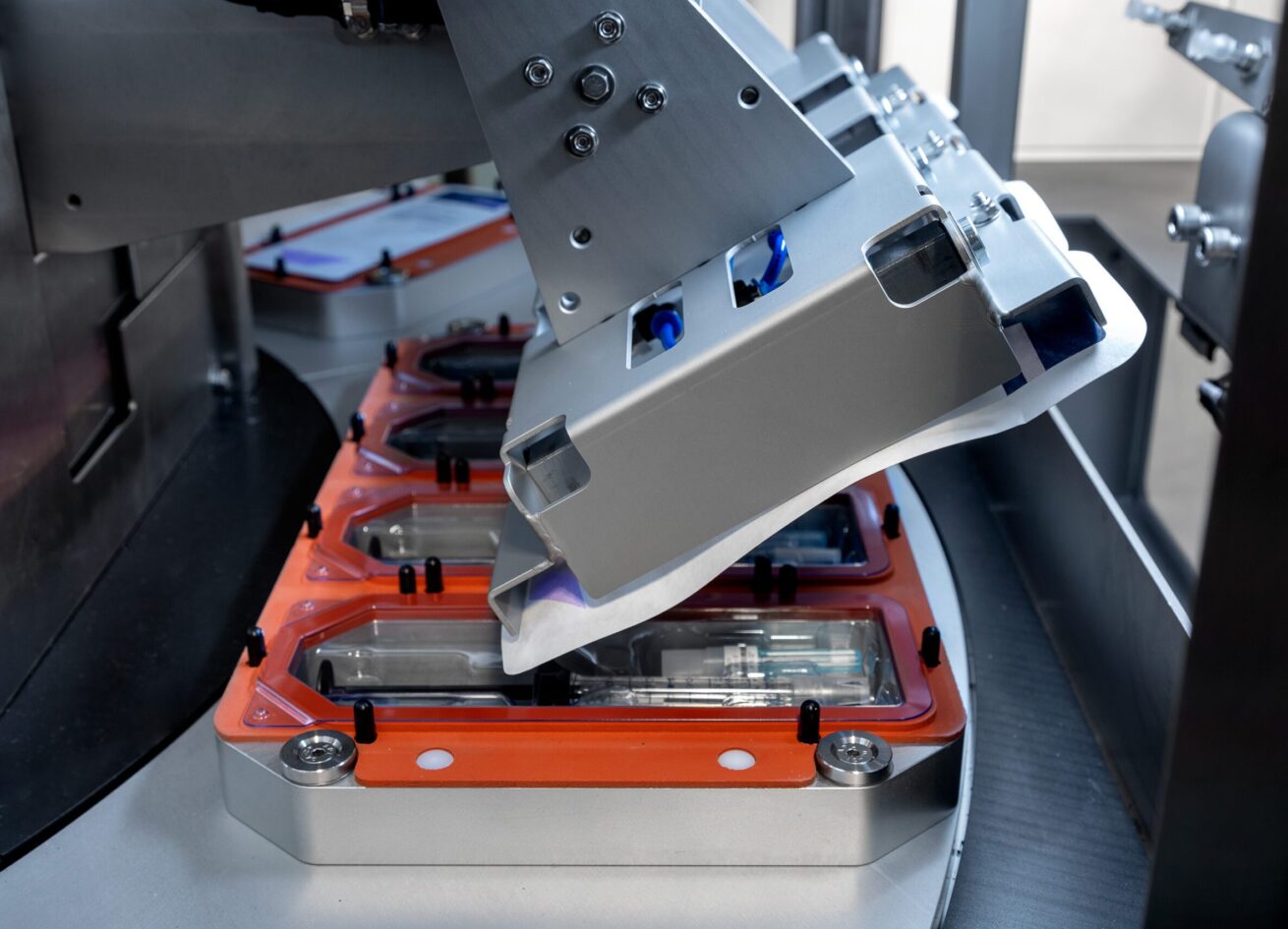

Station 4: The Vision System checks for the presence of all products. This system also checks whether all components of the syringe are present. Next, a Tyvek lid is separated and placed, after which the machine checks whether the lid has been correctly positioned.

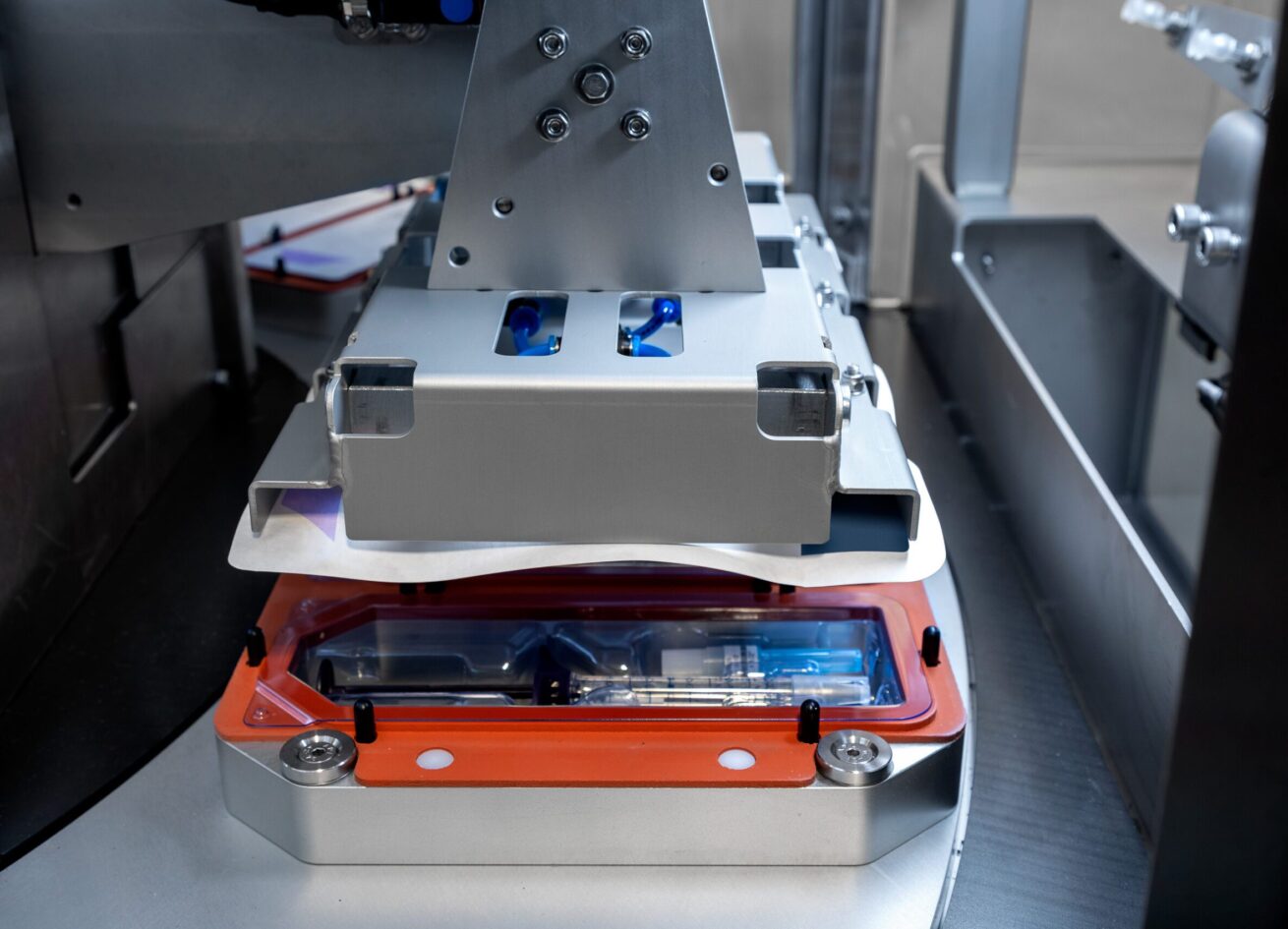

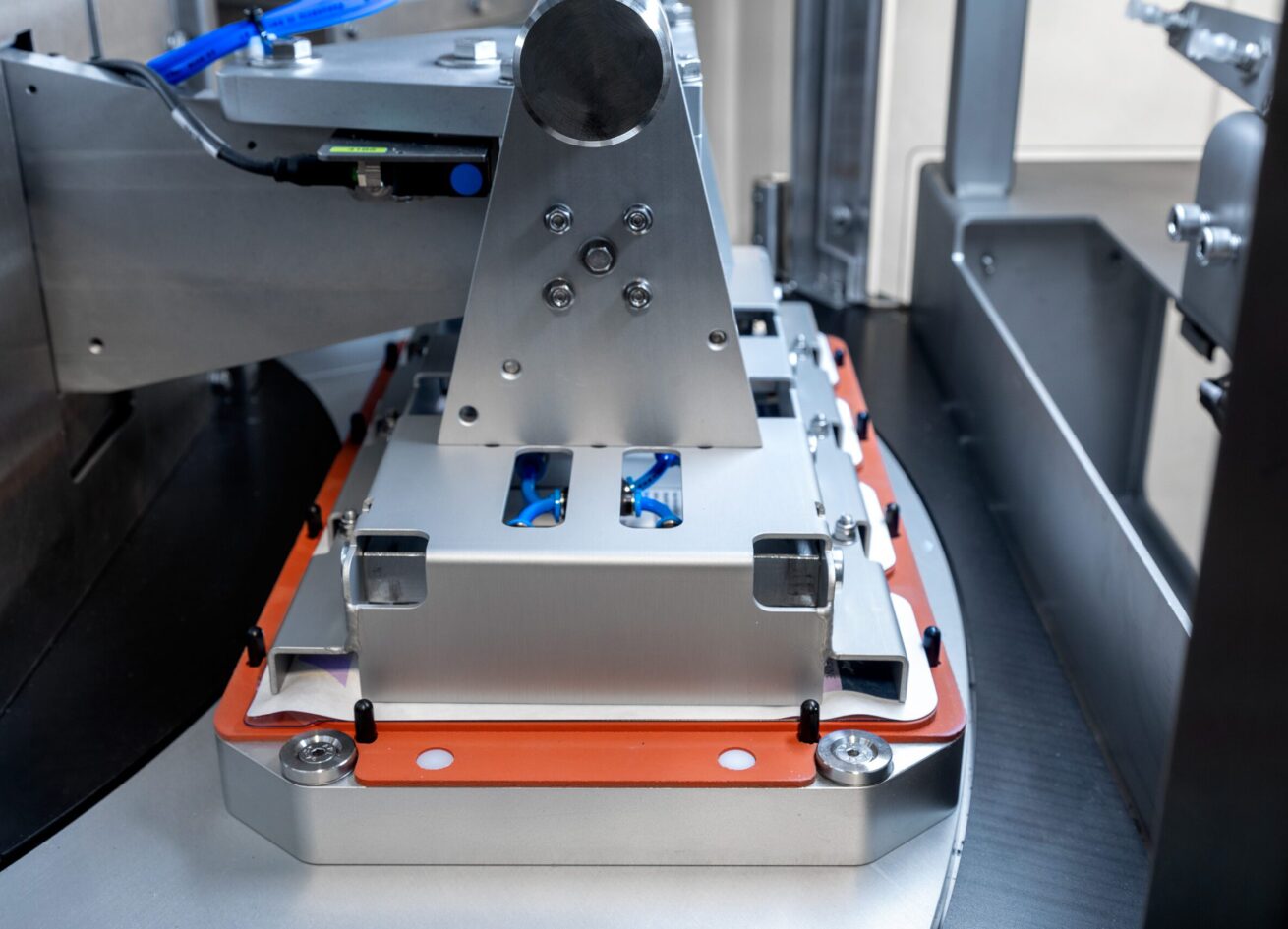

Station 5: The blister is sealed within the agreed seal window.

Station 6: If a product fails the visual inspection or does not meet the preset seal window, the station will reject it. Approved products are fed out of the machine.

This machine makes use of Siemens controls. The LAP-C Platform is suitable for various processes and has a small footprint. The docking stations make sure this machine is accessible at all times.

- Specifications

- Fully customisable to your wishes and requirements

- Assembly and packaging of different products using interchangeable moulds

- Fully validated and compliant with established laws and regulations

- Quality control and validation during assembly and packaging process

- Expandable using our modular LAP-C Platform

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Why choose GTE Engineering?

GTE specialises in designing and producing tailor-made machines for the medical and pharmaceutical industry. Based on your specific needs, we’ll work together on the solutions to the issues you’ve run into.

Curious about what we could do for you?

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)