Think the other way around

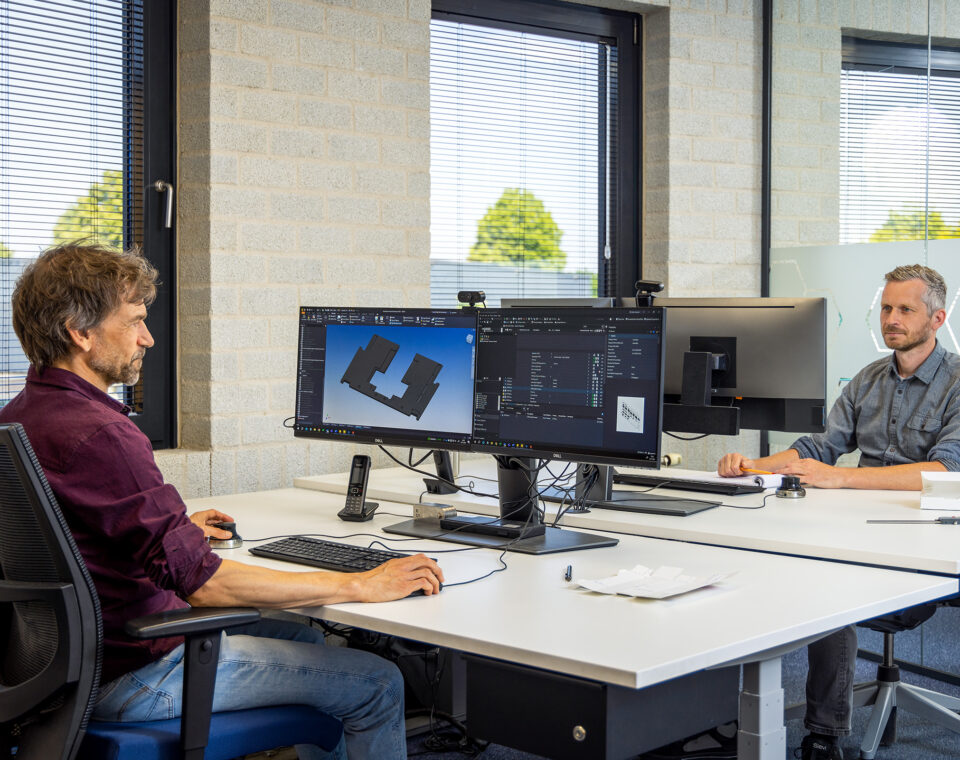

In other words, shifting from the repetitive design of a machine (Engineer to Order – ETO) to a clever standardized machine that incorporates the desired processes (Smart Customization). A prime illustration of smart customization is the personal computer. The PC industry, right from the start, established solid agreements on standardization. This allows virtually any brand of hard drive, graphics card, CD drive, or memory card to connect with almost any motherboard. In machine engineering, the approach often involves working from the product to be produced, with engineers consistently devising new machines “around the product.” Several fixed substructures are reinvented each time. Engineers are expected to create everything themselves and design a structure with as many standard components such as screws, knobs, wheels, motors, etc. If there are no standard substructures, the engineer’s response will often be: No, of course not; the tasks and products are always different, and you cannot standardize that. However, when examining the assembly and/or packaging processes (which is essentially a form of assembly) of various products, you can observe fundamental similarities at the core. For instance, when assembling a syringe or packaging an inhaler, the processes are fundamentally different, but from a more abstract perspective, there are also many similarities.

Similarities

What you typically need for tasks like assembling a syringe or packaging an inhaler are:

- Control cabinet

- Base frame

- Enclosure

- Wiring diagram

- (Product) Transport system

- Component supply systems

According to the Smart Customization philosophy, these substructures can be identical for both products.

Our conclusion is that you can build a base machine on which both products can be assembled and/or packaged (as well as many other products). The assembly or packaging process is then adjusted to the product-specific characteristics and form.

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

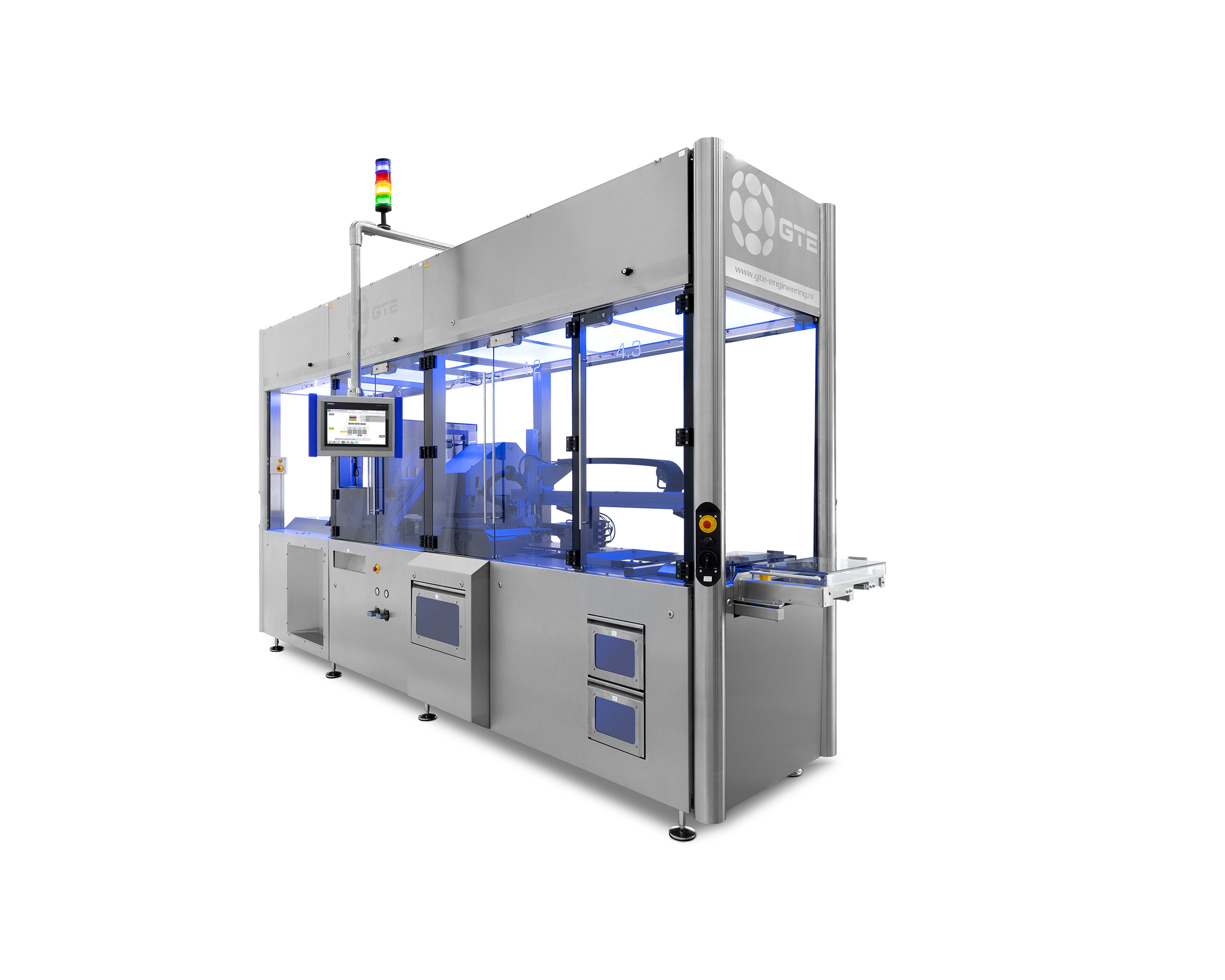

Example platform LAP-C

An example of such a base machine is our LAP-C, or Lean Automation Platform Circular. This platform is suitable for various products. The benefits of this platform:

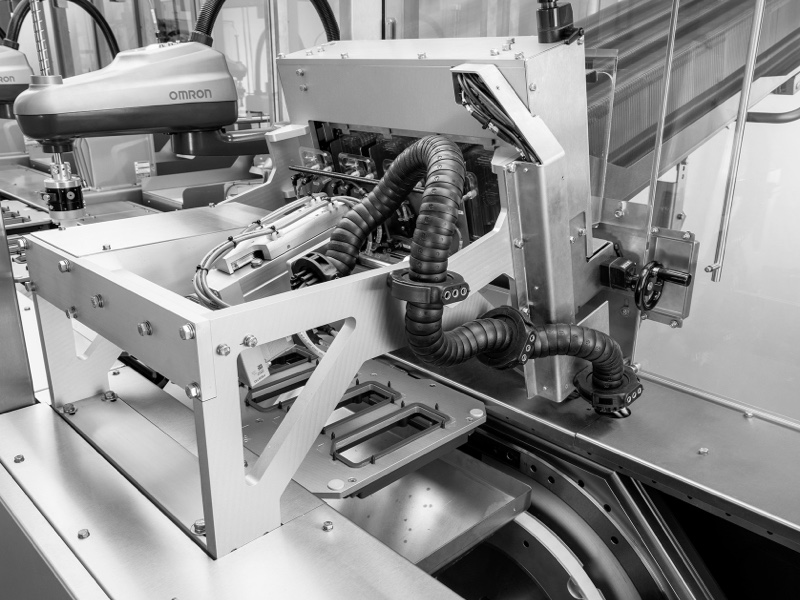

The substructures are fundamentally the same and well-designed, being more robust and qualitatively superior due to significant time and energy invested in these substructures. Every detail has been carefully considered:

- Safety switches are integrated into the enclosure.

- The operator interface is well-thought-out.

- A 3D safety scanner ensures protection only where the hand is near the product. (Typically, a light curtain is used, requiring hands to be completely withdrawn to enable the next step.)

- A cycle table with freely programmable indexing possibilities.

- The drive is quiet, low-maintenance, and precise.

- The enclosure design is effective and has a modern appearance.

- Application of LED panels for communication through light and color.

- Compact footprint.

- Good accessibility for maintenance.

It offers a cost advantage because a base has already been conceptualized. This can be built more frequently and in multiples simultaneously, requiring fewer tests. The design is carefully crafted for cost efficiency.

Shorter lead time because the base is ready. The components are quickly assembled.

Refer to LAP-C for more information on this standard platform.