Sealing requires flexibility

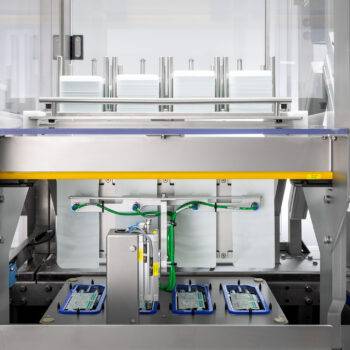

We know how important it is to quickly and efficiently change products, especially in a branch with a lot of high-mix, low-volume production. That’s why all our machines are designed with a quick change-over time in the back of our minds. Changing out components for smaller or larger products is a toolless process and takes a few minutes to half an hour, depending on the amount of parts.

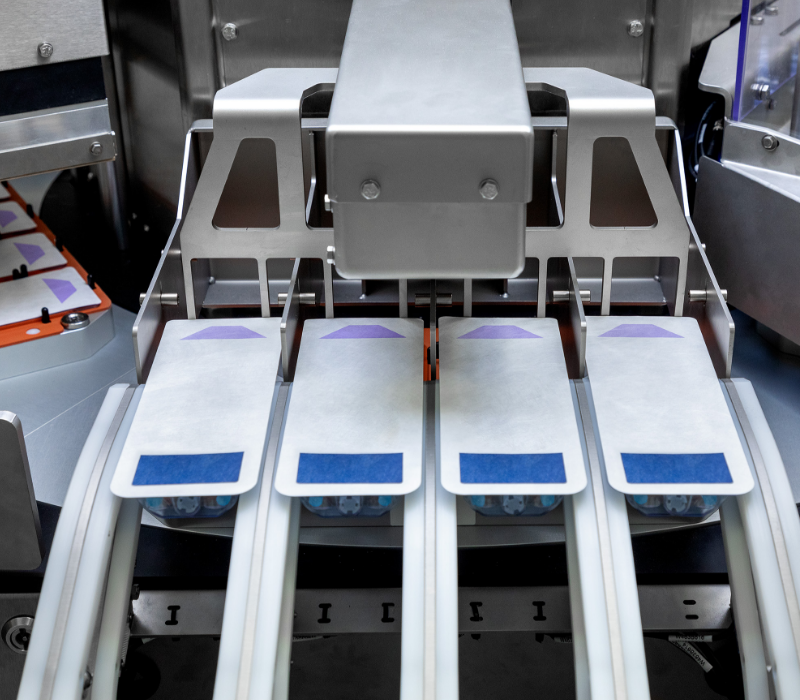

Sealing machine applications

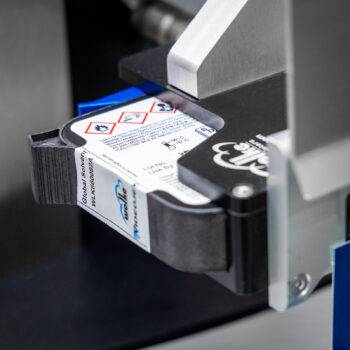

Our sealing machines are changed according to your requirements and the products you need to seal. Whether those are pre-formed blisters, an inner and outer pouch or a container: we have experience in designing machines for almost all packaging materials used in the medical and pharmaceutical industries.

We can also work with a number of materials, like PET-G, A-PET, PP, Tyvek, aluminium, and medical paper.

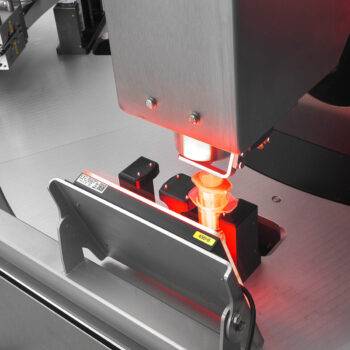

Extensive quality control

Quality, consistency, and reliability are our main focus when designing our machines. That’s why our machines and platforms can be equipped with Vision systems like Cognex. These Vision Checks can be used to detect incorrect package contents, correct orientation of products, a double lid, contamination in the package or between the seal, and, of course, seal quality.

If a machine or platform is furnished with a Vision system, we opt for top-tier cameras such as Cognex, prioritizing reliability and excellence. Is there a specific type of Vision system your company favors? We are open to seamlessly integrating that particular brand into our machines. This way, you won’t need to adjust to a new machine, and we can customize our design to align with your preferences and specifications. This underscores the adaptability that GTE Engineering is committed to providing.

Tailored to your needs

At GTE, we understand that every production process is its own beast. That’s why our solutions are scalable and expandable at a later stage. Whereas a semi-automated solution is often chosen for a clinical trial or start-up, a fully automated solution is usually the best option for an existing production line. All our solutions can be expanded at a later stage with any additional automation measures.

Get more information

Wondering how the machine could be useful for your organisation? Request more information quickly and easily.

"*" indicates required fields

Knowledge & Inspiration

Whitepaper: Everything about vision systems in the pharmaceutical and medical industry

Precision and accuracy are extremely important. Whether they are used for correctly labeling products, or verifying the integrity of packaging, vision systems play a crucial role in any production process. What are their strengths and limitations, how do you prepare for their implementation, and what will the future look like in terms of, for example, AI? We are happy to help you get started; download the free whitepaper!

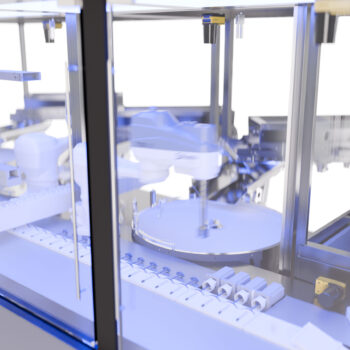

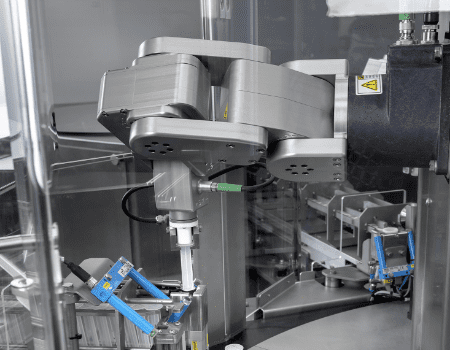

The LAP-C with Mecademic robot

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Considerations when selecting reputable machine developers

What factors should you consider when selecting a machine builder? Do they meet the stringent quality standards of the medical industry? While there are numerous legal regulations in place to ensure machine and product quality, it’s crucial that machine designers and builders are cognizant of these requirements. Additionally, take into account three key factors that can impact both the machine and your product’s quality: the human factor, the product design, and the proficiency of the machine builder.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields