We are GTE Engineering

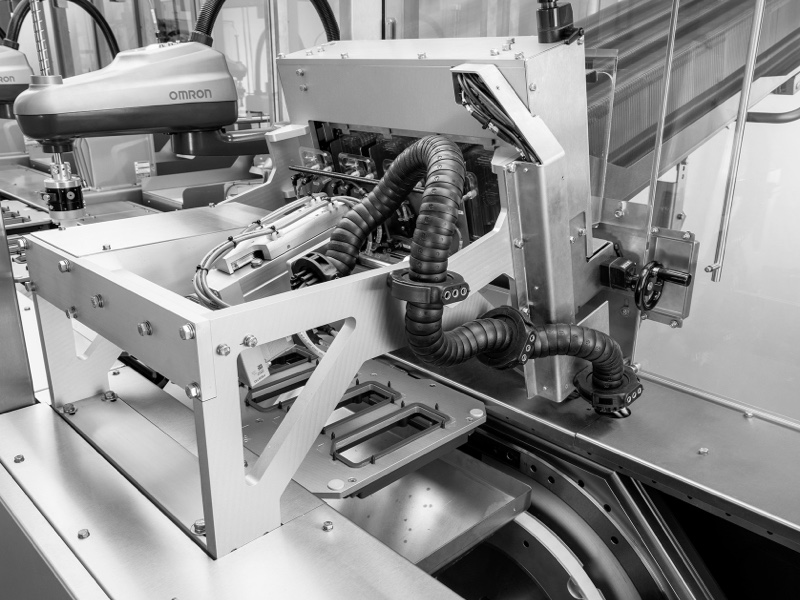

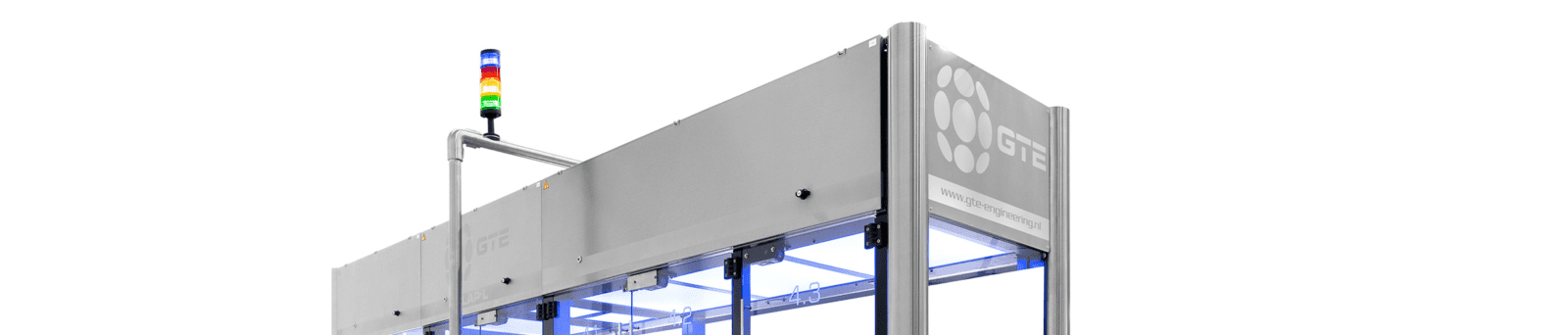

At GTE, we firmly believe that technology has the potential to enhance the well-being and prosperity of society. We collaborate closely with you to devise a modular solution utilizing our GTE Platforms or a customized, sustainable resolution for your needs within the medical or pharmaceutical domain. This approach allows us to actively contribute to the well-being and prosperity of individuals, end-users, and our valued customers.

Benefiting from our extensive experience with clients in the medical and pharmaceutical sectors, you gain a trusted and informed partner. We recognize the paramount significance of quality and validation in our machines, reflecting our commitment to excellence.

Our experts are ready to help you!

We recognize that mastery in every domain is not a universal trait. That’s precisely why each field has its dedicated experts. Allow us to introduce our team!

These are our partners

GTE works exclusively with reliable and established parties to obtain parts for our machines. This way we guarantee that our machines are of the highest possible quality and that you can continue automating your work without any worries.

For example, we work with Siemens controls, Cognex vision systems and many more A-brands. If you, as a customer, have a preference for a particular supplier, we will work with that supplier and integrate it into your solution.

Request a callback

We are happy to discuss how our solutions can be applied to your issue. Leave your contact details so that we can contact you.

"*" indicates required fields

We are present at:

Impressed by what we can do? We would like to demonstrate our machines at one of the events we will be attending soon. Take a look at our calendar to see if we will be in your area soon!

Calendar

Medical Technology Ireland

Medical Technology Ireland Expo and Conference

24-25 September 2025, Galway Racecourse

Pharmapack

22 & 23 January 2025

Paris Expo, Porte de Versailles – Hall 7.2 | Paris, France

Pharmap Congress

PHARMACEUTICAL MANUFACTURING AND PACKAGING CONGRESS 2024

14-15 April, 2025

Berlin, Germany

Would you like to join us?

Are you the talent we’re looking for?

At GTE, we are constantly seeking to enhance our team. Join us and seize the opportunity to grow and bring out the best in yourself and your career in a diverse environment.

If the position you’re looking for isn’t listed in our job openings but you believe you possess the talent we’re seeking, feel free to submit an open application along with your CV and motivation using the button below.

Open application

Discover our knowledge & inspiration

The LAP-C with Mecademic robot

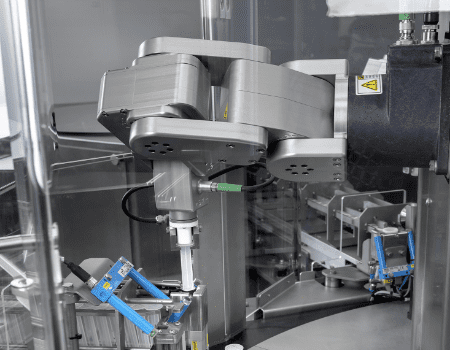

GTE designed and built the LAP-C. A circular platform for assembling and/or packaging medical products. When we design the LAP-C as an assembly machine, we often use a Mecademic robot.

High mix low volume manufacturing

In the pharmaceutical industry, there is a growing demand for high mix low volume manufacturing (HMLV). HMLV signifies that medications and medical devices are increasingly being personalized, tailored more specifically to the patient: a greater variety of medical products combined in smaller quantities.

3D printing in engineering– thinking out of the box

Years ago, in 2001, GTE engineering embraced 3D printing for the creation process of its exclusive machines. Until then it was science fiction. Today we can no longer live without it. How do we use 3D printing at GTE and what advantages does it have?

What is ‘Smart Customization’?

ETO, CTO and Smart Customization. Terms that are more often used in mechanical engineering. But what do these terms mean? Everyone working in mechanical engineering should know what development these words describe.

Considerations when selecting reputable machine developers

What factors should you consider when selecting a machine builder? Do they meet the stringent quality standards of the medical industry? While there are numerous legal regulations in place to ensure machine and product quality, it’s crucial that machine designers and builders are cognizant of these requirements. Additionally, take into account three key factors that can impact both the machine and your product’s quality: the human factor, the product design, and the proficiency of the machine builder.

Accepting downtime is a mortal sin!

Everyone knows that companies are all about production, or ‘adding value’. Value is everything the customer needs and pays for. All other activities support this. That’s why it’s so strange that unplanned downtime is so quickly accepted and seen as ‘normal’. Many companies are not aware of how often the production line comes to a standstill. People quickly get used to it and accept downtime on a production or assembly line. However, a production line coming to a standstill is disastrous for the organization. If no value is added, the entire organization comes to a standstill.

Let us call you back

Curious about how our machines can be used within your organization? Request more information quickly and easily.

"*" indicates required fields

We are ready to help you!

Mercuriusplein 45971 LW Grubbenvorst (Nederland)